Cutting Tools

The Case For Copy Milling Cutters

The round-insert 'button cutter' can bring a high metal removal rate to a low horsepower machining center.

Read MoreTooling Reduces 21 Minute Job To 9 Minutes

Shop leadership was looking for a way to reduce the time it took to complete a very difficult boring job. The job took 21 minutes per part to complete with multiple roughing and finishing processes. It required 10 minutes of hone time.

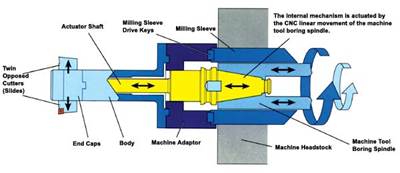

Read MoreBoring Bar Adjusts In The Cut

Firms that do a lot of boring of gear boxes, valves, castings and other complex components on horizontal boring mills, floor-type boring mills and similar horizontal-spindle machines should be interested in Controlled Boring Bars and Contouring Heads.

Read MoreNew Borders For Swiss-Type Turning

The traditional niche may be too narrow. This shop uses sliding-headstock lathes for jobs that wouldn't normally be run on this type of machine.

Read MoreHigh Speed Machining Of Dies And Molds (Revisited)

A new machine may not be needed— just changes in the process.

Read MoreAviation Component Supplier Cuts Setup Time With Productivity Partnership

This shop turned to a tool supplier to help cut milling time on one alloy steel hydraulic body by 63 percent. The success led to a broader Productivity Improvement Program that identified some $87,000 in potential annual savings, and ultimately to a $600,000 payoff by introducing a quick-change modular tooling system.

Read MoreWhat's Happening With Cutting Tools

Shops in North America are machining high-value parts, including parts made from difficult-to-machine metals, as a larger share of their workload. When the MMS editors recently listed topics related to cutting tools that we intend to watch closely, we found this one factor—difficulty—at the heart of much of what is changing about shops' use of tooling.

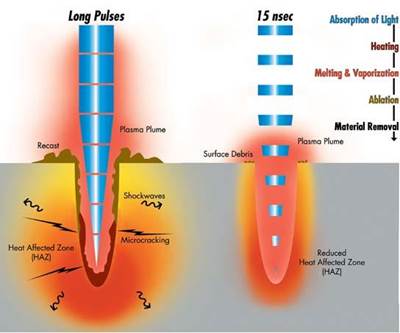

Read MoreNon-Traditional Methods For Making Small Holes

Consider these alternatives when conventional drilling can't do the job.

Read MoreThe Role Of Balance In High Speed Finish Boring

Precision boring is particularly vulnerable to unbalance, but not every high speed boring application demands a balanceable tool.

Read MoreGood Planning Makes Better Threaded Holes

Hole making is as common an operation as exists in metalworking. Tapping those holes is also very common. Finding a way to get quality threads and using efficient processing are ongoing jobs for this Indiana shop.

Read More

.png;maxWidth=300;quality=90)