Non-Traditional Methods For Making Small Holes

Consider these alternatives when conventional drilling can't do the job.

Share

Not too long ago, a hole the size of a human hair (about 0.003 inch in diameter) was about the smallest hole that could be made using conventional machine tools on a production basis. Today, advances in the fields of medical devices, communications, optics, electronics, computers and others have created a need for holes that are straighter, more accurate, better defined—and in many cases much smaller in diameter than a human hair.

Today, that need is being met by not-so-new but little-known non-conventional hole-making techniques, some of which are described in the following pages. These techniques not only have prompted the development of machine tools designed with small hole making in mind, but they also have produced specialized contract shops that, by serving the trend toward miniaturization, are on the leading edge of new-product development.

Laser Microdrilling

Recent improvements in ultraviolet (UV) light lasers have made them a very competitive tool for microdrilling and other micromachining applications. The Gator (photo on page 77) is a compact, diode-pumped solid-state laser (DPSSL) made by Lambda Physik Inc., Ft. Lauderdale, Florida. It offers a combination of high peak power, high repetition rates and beam quality that makes it suitable for drilling holes as small as 10 micrometers (0.0004 inch) diameter in stainless and carbon steels, titanium, ceramics, silicon and other hard materials up to about 1 mm thick.

"Laser drilling of small holes has been around for 30 years," explains Mike Heglin, vice president of scientific and industrial sales for Lambda Physik. "The first systems were installed to drill numerous, small, cooling holes in turbine components for the aircraft/aerospace industry. Until recently, such systems required a lot of maintenance—replacement of the optics, periodic replacement of the flashlamp, realigning the optics within the laser, and so forth. Despite the constant attention, maintaining uptime remained a problem. Would-be users were afraid to buy a laser for fear that they'd need someone with a Ph.D. to keep it running.

Shorter Pulses Equal Better Holes

"The diode laser has changed all that," Mr. Heglin continues. "Diodes allow the laser to run with the reliability of, say, an electric motor. We expect our lasers to provide 20,000 to 30,000 hours of continuous operation—that's up to 10 years of running time depending on the number of shifts that the customer operates."

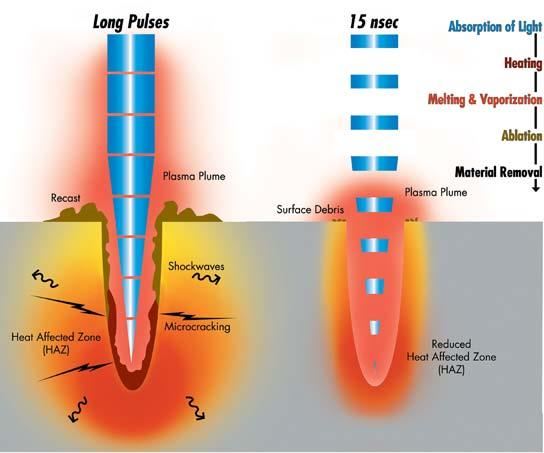

Mr. Heglin notes that while the quality of laser-drilled holes has been acceptable for most applications in the past, it did not measure up for more demanding applications such as holes for fuel injection components. The new diode laser produces a pulse that is much shorter, 15 nanoseconds (billionths of a second), compared to milliseconds for the older style lasers. (See diagram on page 78.) That plus a much shorter wavelength results in a greater cutting efficiency. Less heat is generated in the part as well: Because of the high power intensity created by the short pulse, much of the material is removed in a photo-ablative state rather than a thermal melting state, which results in a much smaller recast layer and better quality holes.

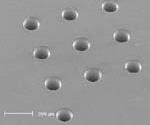

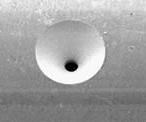

A study conducted by Lambda Physik demonstrated that its Model G1064 Gator (with an average power greater than 10 watts) can drill holes in 1 mm-thick steel plate at a rate of 10 mm per second. Close-ups of holes (shown on page 78) drilled in varying thicknesses of steel attest to the quality of the holes.

Mr. Heglin adds with satisfaction that some automotive companies and their suppliers reevaluated the use of lasers for drilling fuel injection components and have put systems into production. He cites as another example of precision laser drilling nozzles used in the manufacture of fibers.

In addition to providing more accurate, better defined, drilled holes, the laser drilling process offers a lot of flexibility. Once the laser beam creates a starting hole, it can, just as with CO2 laser cutting or wire EDMing, be moved like a jigsaw to create a hole of any desired size and shape. Laser drilling is faster than, say, the EDM process, and it requires no hard tooling. Also, where EDM drilling and EB drilling are limited to processing conductive materials, the laser drill can be used to drill materials ranging from soft plastics to the hardest metals . . . even diamonds. Finally, the Gator and other diode lasers are relatively compact—the Gator is the size of a toaster oven—which means that they can usually be accommodated easily in existing production lines and relocated when production requirements change.

Electron Beam Drilling

Electron Beam (EB) drilling was developed by Karl-Heinz Steigerwald in Germany in the early 1950s, to drill holes in jewel bearings for mechanical watches. His work eventually led to the creation of Steigerwald Strahltechnik GmbH (Munich, Germany), a company that manufactures EB drilling machines capable of producing holes from about 0.002 inch to 0.060 inch in diameter in metals and other conductive materials from 0.010 inch to 0.250 inch thick.

EB drilling is similar to the laser drilling in that energy is created and precisely focused on a workpiece to bring about highly localized melting. In the EB process, an electrically heated cathode produces electrons that are accelerated by an electrical field applied between a cathode and anode at a very high voltage. A modulating electrode controls the intensity of the electron beam, which is focused onto the workpiece through an electromagnetic lens to power densities of 100 million watts or more per square centimeter.

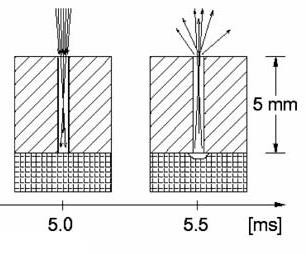

CNC control, specially designed for the EB drilling process, controls the main drilling parameters and the axial movements of the workpiece and beam. Its main job is to keep the pulse duration and beam current level consistent from pulse to pulse (unless variations are required by the drilling program). In the EB drilling process, the focused electron beam concentrates so much power at the hole site that it creates a "vapor capillary" surrounded by a cylinder of molten material. As the depth of cut increases (diagram on page 81), the beam gets in the way of the molten metal, preventing it from escaping out of the bore.

To expel the molten material and to help maintain uniform size from hole to hole, a backing material is applied to the underside of the workpiece material being drilled. When the electron beam breaks through the workpiece material, the backing material reacts to the beam by producing a large volume of gas that expands explosively up the capillary, taking with it the molten material. A trace amount of molten material is left behind as a recast layer, however it does not create oxidation problems since the EB drilling is done in a vacuum.

2000 Holes/Second

The most important advantage of the EB drilling process is its ability to produce very large numbers of holes quickly. The process can create a hole with a single millisecond (thousandth-of-a-second) pulse of the electron beam, and the workpiece and beam move relative to each other making possible extraordinary hole-making rates. For example, 100 micrometer diameter holes can be drilled in 0.3 mm-thick sheet at 1,500 to 2,000 holes per second.

As is true of most hole-making processes, the time required to make the hole varies inversely with the size of the hole and the thickness of the material. Thus, the rate drops off to a "mere" 20 holes per second when EB drilling 5 mm-deep, 0.7 mm-diameter holes—still many times faster than any other process. Thus, in applications where the part requires tens of thousands or millions of tiny holes, such as a very fine filter screen, the EB drilling process is hard to beat.

Workpieces drilled by the EB process tend to fall into two groups: flat sheets of metal that are typically wrapped around a mandrel to form a cylinder for processing as shown above; and workpieces with symmetrical and asymmetrical shapes (photos on pages 76 and 77). Both types of parts are mounted on workpiece holders with up to four- and five-axis movement capabilities. For a cylindrical part, the most common movement is continuous rotation about its major axis. The beam moves simultaneously with the part, in a "flying beam" fashion, to produce the holes in the shortest possible time.

Holes of various shapes (straight walls, bowed-walls, large or small bell-mouthed openings, and so forth) can be formed by varying the drilling parameters. The EB drilled hole typically is characterized by a slight bell-mouthing at the beam entry point. There are no breakthrough problems: The underside of the hole is typically sharp and burr-free. Oval holes and slots can be produced as well as round holes. The holes can be normal to the workpiece surface or drilled at angles up to 25 degrees.

The repeatability of the EB drilling process provides hole size accurate to ±0.001 inch and location accuracy to ±0.0005 inch. Aspect ratios (hole depth to diameter) of 25:1 can be achieved.

Finally, the EB drilling process is largely automatic. Once the workpiece-drilling program is downloaded to the machine, the operator's responsibilities consist primarily of monitoring the operation of the machine and loading-unloading workpieces. According to the manufacturer, the EB drilling generator has no parts that wear in use. The cathode filament, which is inexpensive, is the only replacement part.

Owens Corning uses the EB drilling process to fabricate parts for its proprietary glass-making equipment. The parts are made at the company's Ridgeview Electron Beam Drilling and CNC Machining facility in Duncan, South Carolina, which also provides contract machining services to firms in the aerospace, food, filtration, consumer products and other industries.

6 Million Holes/Part

"Most of the parts that we EB drill are used in filter applications," explains Will Bowman, general manager of OC Ridgeview. "For example, for one of our customers we EB drill 6 million 0.006-inch-diameter holes in a 0.125-inch-thick, stainless steel disk just over 24 inches in diameter. We also EB drill ceramics. Typically, holes are drilled in ceramics while they are in the green state, but with EB drilling, we can drill holes in fired alumina workpieces up to 0.250 inch thick."

OC Ridgeview will process orders as small as one part. Mr. Bowman emphasizes, however, that for the EB drilling process to be cost effective, the part should require several hundred holes from 0.001 inch to 0.060 inch in diameter. "We can hold size tolerances of ±0.001 inch," he adds. "If the application requires tighter tolerances, EDM is probably the better process. If the application calls for fewer holes, laser drilling may be best. But when the application calls for hundreds to millions of holes, we offer the most efficient process."

EDM Microdrilling

A third process for making small holes is EDM microdrilling. The EDM microdrilling machine is essentially a sinker or ram-type EDM machine with some interesting modifications that enable it to drill holes as small as 0.0002 inch in diameter.

Pure tungsten wire is the preferred electrode material for some users because of its exceptional wear resistance; the fabricated electrode retains its size and shape longer, making for longer tool life and greater hole-to-hole consistency. Others choose tungsten carbide for the EDM electrode material because its micrograin structure is more conducive to forming small diameters in the 5 to 10 micrometer range. The electrode is typically rotated while cutting in order to promote flushing of residues.

An essential component of the EDM microdrilling machine is a stereo microscope (photo on page 82) that is used to position the electrode at the workpiece surface before the start of cutting, and to monitor the EDM drilling operation. The sparking taking place can be seen only faintly with the 30× microscope, however an experienced operator can tell from the color of the discharge whether the drilling is proceeding satisfactorily.

EDM microdrilling requires only 1 percent to 10 percent of the current used by a conventional ram-type EDM machine. Of the three processes described in these pages, EDM microdrilling is probably the most controllable. Power settings can be varied to satisfy requirements for each job. Higher settings permit more aggressive drilling (more holes per hour). Finer settings permit greater dimensional accuracy and better surface finish: Holes can be "polished" by reducing the discharge energy to an infinitesimal amount.

Like the EB drilling process, EDM microdrilling is limited to conductive materials. However, the process is "blind" to considerations of material hardness, drilling with ease, stainless steel, carbide and other metals that are difficult to machine by conventional methods. Holes can be drilled at an angle to the surface, and there is no problem with "walking" when starting a hole on a curved surface.

Optimation Inc. Burr-Free Microhole Div., Midvale, Utah, specializes in EDM microdrilling of holes. The firm uses the EDM microdrilling process to make a range of pinhole apertures, which are small, precision holes drilled in foil that are used as standards by the laser, optics and other industries. They demonstrate the very small holes that the shop is capable of producing by the EDM microdrilling process. The apertures range in size from 10 micrometers (0.0004-inch) diameter for the smallest to 1,000 micrometer (0.040-inch) diameter for the largest. Each calibrated aperture is centered on a 3/8-inch diameter, 0.0005-inch-thick stainless steel disk. Sets of apertures in various sizes are available.

The apertures represent just a small part of Optimation's sales, however. Most of the shop's sales activity involves contract EDM microdrilling of metals for the aerospace, medical, computer and other industries that manufacture miniature parts. Dean Jorgensen, Optimation's president, cites some examples of recently completed jobs: "We recently did a job that involved drilling a 125 micrometer (0.005-inch) diameter hole in 2 mm-thick Invar for a fiber optics firm. And we're currently drilling a 200 micrometer hole through 1-mm-thick tantalum for National Laboratories. If you need a 25 micrometer hole in a stainless steel wafer for a spatial filter for the optical industry, a calibrated hole for leak detection or an X-ray aperture, we're the place to go."

Optimation produces EDM microdrilled holes on two Micro EDM machines supplied by Panasonic Factory Automation Co., Franklin Park, Illinois. The shop also produces microholes by the laser drilling process. Mr. Jorgensen explains that, of the two processes, laser drilling is faster and less expensive. "With the laser, one zap and your hole is done," he notes. "With EDM microdrilling, on the other hand, we must first make the electrode (a procedure that is nearly as demanding as drilling the hole), put the electrode on the machine, and then wait seconds to minutes for the machine to drill the hole.

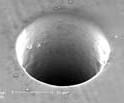

"However, in applications where hole size and location accuracy are critical—and that is increasingly becoming the case where microholes are involved—EDM microdrilling is the more precise method," he continues. "In addition, we can do things with the EDM process that just can't be done with a laser. For example, we had to drill a hole in the shape of a truncated cone for a customer in the textile industry. The hole, like that shown above, tapers from 0.008 inch diameter at the top to a precisely centered 42 micrometer hole (±1 micrometer) at the bottom—something that simply could not have been done any other way."

If your operations involve machining large workpieces exclusively, you may never need the microhole-drilling equipment and services described in the preceding pages. However, if you are seeing more frequent RFQs that involve holes that are just too small for your machines (and tool crib), remember that there are non-traditional machines capable of producing those small holes and contract shops with such machines that are waiting for you to call.

Related Content

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

%20drilling%20machine.jpg;width=860)