Cutting Tools

Boosting Productivity For Turbine Engine Part Makers

Compared with common steel, the heat-resistant super alloys (HRSAs) and other hard metals used in jet engines and ground-based turbines require far longer cycle times per part. Advanced cutting inserts can boost machining throughput with these materials, but achieving these gains requires proper tooling selection and proper implementation.

Read MorePallet Adjusts To Different Tool Diameters

A tool-handling device developed for more efficient automated production of cutting tools may also be helpful for machine shops that have their own in-house area for tool regrinding or making custom tools.

Read MoreCompany Invests In HMC To Keep Pace With Growth

Since its installation, this HMC has dramatically reduced floor-to-floor times on the manufacture of precision reamers, which are used for expanding oil well bore holes during directional drilling operations.

Read MoreLaser Toolsetter Solves Moldmaker's Quality And Productivity Challenges

Prior to toolsetter installation, Desenco personnel report that it was 'almost impossible' to attain accurate Z depths and repeatability in the Z axis.

Read MoreMilling System Puts Productivity In Fast Lane

When this company won a contract to machine automotive parts for a customer, they were faced with the need for a milling tool that could meet tighter cycle times, enable machining centers to perform multiple tasks, maximize the life of milling tools and reduce tool inventory.

Read MoreSmall-Diameter Drilling Under Scrutiny

Today's smooth-running high rpm spindles not only allow shops to cut faster with standard tool designs, they also unlock the potential of tiny tools.

Read MoreFaster Off-Line Setup Helps Reduce Turret Tool Costs

At this company, a contract manufacturer specializing in sheet metal fabrication, finding ways to get more out of its turret punching operations has become a passion.

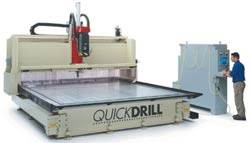

Read MoreA Better Process For Hole Making

This company is in the business of drilling millions of holes in very large parts. As an established manufacturer of heat exchangers and components, the Calgary, Alberta-based company drills an estimated 1.5 million holes per year in metal plates.

Read MoreOn The Path To Automation

Implementing an integrated tooling system proved to be this mold shop's first step toward automated operation of its electrical discharge machines and graphite mills. Today, the shop's robotic cells can run around the clock in an unattended mode.

Read MoreInserts For Difficult Materials

Economic efficiency is an important consideration when choosing tools for challenging metals.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)