Cutting Tools

Heavy-Duty Hole Making

A modular drilling and boring system has changed this oilfield product manufacturer's holemaking operations.

Read MoreDeep Thinking

A job shop that specializes in gundrilling points out the special requirements of machining deep holes.

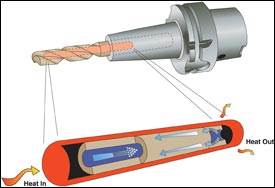

Read MoreDrilling Dry With A Heat Pipe

It's widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It's also among the most difficult operations to control from a thermal perspective.

Read MoreAnother Way To Square—Or Is It Perpendicular?—It Up

There are a number of tools available for shop personnel to evaluate the right angle relationship between two surfaces. The basic machinist square has a number of variations, the most common being the hardened steel square used to check right angles and set up milling and drilling machines.

Read MoreThe Overhang Effect

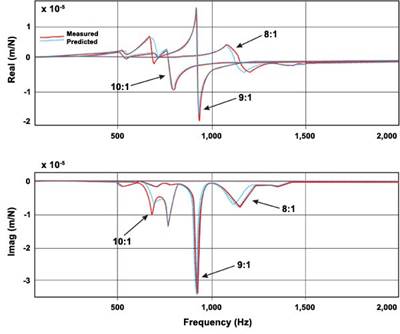

The length by which the tool extends from the toolholder is a variable that can be used to 'tune' the machining process. Contrary to what you may expect, increasing the tool's L:D ratio may reduce chatter and result in more productive milling.

Read MoreManufacturer Learns How To Use Cutting Tools More Effectively

In today's competitive climate, cutting tool manufacturers have to do more than just produce tools--they have to help customers use those tools effectively.

Read MoreA Boring System For Non-Round Holes

Machining an out-of-round bore is easy if you're not particular about the location or magnitude of the roundness error. But accurately machining a hole that has a precisely defined non-round profile is a capability that would seem to be well beyond what a standard boring bar can accomplish.

Read MoreHarley Davidson Parts Manufacturer Mills A 'Mile Of Aluminum'

This designer and manufacturer of Harley-Davidson aftermarket motorcycle engines and related components, is using PCD milling to finish engine cases, oil pumps, rocker boxes, inner and outer primary engine covers, and transmission cases and covers.

Read MoreIntegrated Tool Management

Bridging the gap between process engineering and shop floor activities can bring about a "deproliferation" of cutting tools.

Read MoreCMM Locks In Inspection And Productivity

This company, established more than 140 years ago, manufactures a high volume of brass padlocks annually. They are made on two large rotary transfer machines with drilling capabilities. The company is also doing reverse engineering for tooling purposes for other machines it uses in its manufacturing and assembly departments.

Read More

.png;maxWidth=300;quality=90)