Drilling Dry With A Heat Pipe

It's widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It's also among the most difficult operations to control from a thermal perspective.

Share

It’s widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It’s also among the most difficult operations to control from a thermal perspective.

Unlike milling and several other cutting operations, a drill tip is in continuous metal-to-metal contact and—as a result— generates a lot of heat. Heat is the enemy of tool life. Exacerbating drilling operations is the close confines of the hole itself. There isn’t much room to get coolant in and chips out.

Traditionally, coolant or oil was applied externally using a flood. More recently coolant is applied through the tool under normal or high pressure. Coolant was the primary means to cool drills and evacuate chips. This system works well by extending tool life and often allows higher drilling feeds and speeds.

But there is a movement afoot among manufacturers to reduce the amount of coolant used in metalcutting operations. Drivers for this come from environmental considerations about worker exposure to coolant mist and from a cost reduction perspective. Dry or semi-dry milling is becoming a fairly common practice especially in Europe. It’s gaining applications here in the United States.

But unlike milling, drilling remains a tough operation for performing dry because of the thermal difficulties. A new drill design concept created by the research and new product development group at Lamb Technicon (Chesterfield Township, Michigan) shows promise for practical dry drilling of holes.

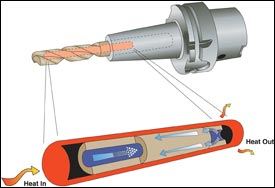

“We took a device that has been used in other fields called a heat pipe,” says Dr. Philip Szuba, who is director of Lamb’s research and new product development group. “The first design we built was comprised of a copper pipe inserted into a hole gundrilled into the drill. The copper pipe was then partially filled with fluid (water seems to work best) and capped off. Later, tests showed the copper insert was not needed so we now simply make a hole in the drill, partially fill it with water, and cap it off.”

The heat pipe works with no moving parts or electronics. In operation, the drill point, which is the prime focus of heat because of its continuous contact with the workpiece, heats up. The heat of the drill point migrated up the body of the drill. As the heat transfers from the drill tip to the heat pipe, the fluid gets hot and boils, creating steam inside the pipe.

Steam rises, and because it is hotter than the liquid water it takes some of the heat away from the drill point and further up the drill shank where the toolholder mass (V-flange or HSK) is located. This convection action allows the toolholder to act as a heat sink and bleed the heat away from the drill. As the heat is dissipated, the steam cools and condenses back to liquid water. The liquid sinks down the heat pipe, and the cycle repeats. In effect, the heat pipe is a thermal driven pump that moves heat away from the drill point and, according to Dr. Szuba, has resulted in a 40 to 60 percent increase in tool life over drilling dry alone.

So far the tests at Lamb have involved uncoated HSS drills. To better analyze the heat pipe, a 3/4-inch drill has been used to cut in cast iron. Dr. Szuba says that scaling up the heat pipe should pose no problems, and he expects it to be practical down to around a ¼ inch diameter drill. He also sees no impediment to using the heat pipe with other drill materials and coatings.

For drill point orientations other than vertical, a wick is used inside the heat pipe. It provides a channel for capillary action to occur and allows the heat pump to work regardless of the tool point orientation.

The development of this heat pipe drill is being driven by Lamb’s customers who in turn are being pressured from various quarters to reduce the health and environmental issues and costs associated with cutting wet without dramatic compromise in tool life or performance. For this builder, necessity is indeed the mother of invention—and the heat pipe is, for the right application, a clever invention.

Related Content

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreHeule Tool Enables Spot Facing of Difficult-to-Reach Areas

The manually actuated bkac spot facing tool is well suited for large boring mills and other open-air machines.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)