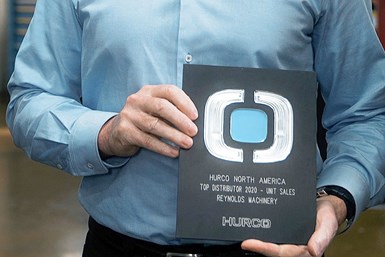

Reynolds Machinery Recognized As 2020 Top Hurco Distributor

Hurco has recognized Reynolds Machinery as its 2020 top distributor in unit sales — a first for Reynolds, though it has come close several times in the past.

Share

Hurco has recognized Reynolds Machinery, the exclusive distributor for Hurco CNC machine sales and service in Ohio, with the Hurco 2020 Top Unit Sales Award for North America.

“We’re very proud to win the #1 distributor award,” says Scott Mays, president of Reynolds Machinery. “We’re a competitive group here at Reynolds and the entire team worked very hard all year, so it means a lot to get the win!”

“Reynolds Machinery’s winning formula serves their customers well because they focus on support and service after the sale,” says Scott Camloh, national sales manager for Hurco. “Not only are they extremely knowledgeable about Hurco products and the advantages of the Hurco control, they are responsive to their customers and understand how to help them gain the greatest benefits from the powerful technology that is inherent to Hurco CNC machines.”

While Reynolds has always been near the top of Hurco’s rankings, and often took 2nd place during its past 25 years representing Hurco, this is Reynolds’ first time in the top spot. This is also the first year Reynolds has been able to offer customers the Hurco Automation Package from ProCobots. Hurco’s Practical Job Shop Automation package integrates the programming of the collaborative robot into the Hurco control.

“The biggest advantage of the Hurco Automation package is the ease of programming and the flexibility it gives shops,” Mays says. “If you can program a Hurco, you can program the cobot, which eliminates the need to call an integrator each time you set up a new job. It makes automation practical and easy, especially for high-mix manufacturing environments.”

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.