CNC Tech Talks

CNC Tech Talk: 2 Lesser-Known Ways to Trigger the Skip Signal

Here are two lesser-known ways to trigger the skip signal.

Read More3 Ways to Help New Engineers Understand Manufacturing

Priorities, processes and personnel are three things new engineers must understand about the shop floor.

Read More5 Mistakes We Find in Most CNC Machine Programs

While the mistakes listed here will not sound an alarm or cause a program to fail, they will cause confusion, wasted time and scrap parts.

Read MoreHow to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

Read MoreHow to Effectively Train CNC Machine Operators

A blended-learning approach uses external resources to teach the basics, saving in-house training for company-specific issues.

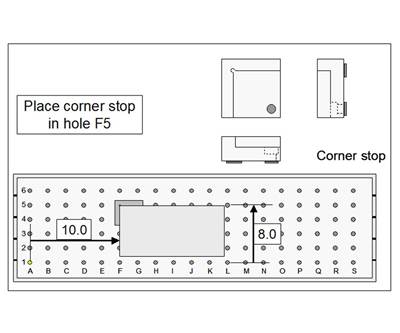

Read More5 Ways the External Work Offset Can Help You

External work offsets can be valuable because they let you shift the point of reference for fixture offset entries from the machine’s home position to a more logical one.

Read MoreWhat to Include When Developing Your Company Playbook

Like a sports team, your company can also benefit from a written plan.

Read More5 Things New CNC Machine Operators Must Know

These subjects are the building blocks of training newcomers on a specific CNC machine tool.

Read MoreMonitoring Time for Preventive Maintenance Tasks

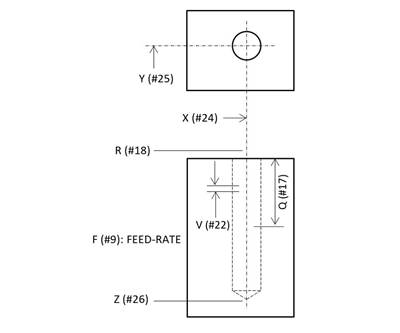

Not all maintenance tasks should be performed based on a calendar date. You can use a custom macro to monitor your machines.

Read MoreConverting Time and Date to a More Useful Format

FANUC and FANUC-compatible CNCs have multiple ways to monitor time. They are accessed by four system variables: milliseconds clock, hours clock, current date and current time. Here’s how to format information in a helpful way.

Read More