CNC Tech Talks

3 Examples of Machines that Combine Manufacturing Methods

Certain “hybrid” machines combine some form of additive manufacturing with CNC subtractive manufacturing. Columnist Mike Lynch, President of CNC Concepts Inc., explores three types of these machines here.

Read MoreFive Areas of CNC Machining to Simplify With G Code

Optimizing G code to make CNC setup and operation simpler is a great way to improve CNC productivity and sometimes prevent errors.

Read MoreFive Safety Considerations for CNC Machinists

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime.

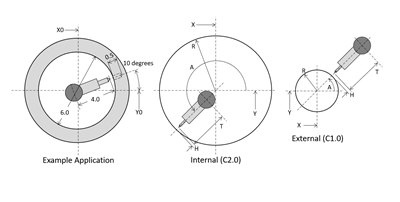

Read MoreHow to Drill Holes With a Right-Angle Head

Drilling with a right-angle head in a machining center spindle can be tricky – doubly so if the hole must be peck-drilled. A custom macro and careful attention to positioning help ensure smooth production.

Watch5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read More6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

Read MoreImprove CNC Programs With User-Defined G, M Codes

CNC operators can program user-defined G and M codes to call custom macros and improve upon or replace existing codes, which can in turn improve production.

Read More