CNC Tech Talks

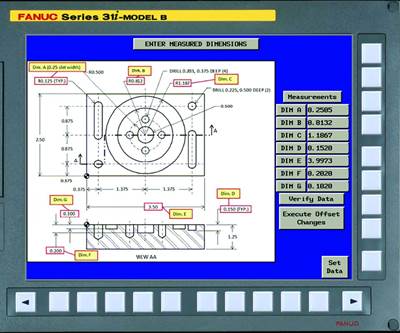

Holding Size with Tight Tolerances

Tolerances of less than 25 microns can be challenging to achieve and hold. Here are some suggestions for holding them for multiple workpieces.

Read MoreHow to Deal with Complexities That Affect Worker Skill Levels

The goal must be to keep tasks as simple as possible for those who perform them.

Read More3D Printers: Using CNC Machines to Adapt Through Similarities

By thinking of 3D printers like any other CNC machine, users can find it easier to adapt to the technology.

Read MoreTracking Time with Custom Macro

System variables allow for time-based applications like tool-life monitoring, preventive maintenance, sampling inspections and machine warm-up.

Read MoreThe Effect of Lot Size on Productivity

The more parts to be produced, the more elaborate the manufacturing process. Here are some other important considerations that can impact productivity.

Read MoreControlling Your CNC Display Screens

CNC manufacturers have begun offering programs that allow end users to customize how display screen pages look and work.

Read MoreMaintaining Productivity with Repeat Business

Recurring tasks need to be streamlined and sometimes performed offline.

Read MoreTesting Job Applicants for CNC Programming Proficiency

The best way to confirm prior experience of new CNC programmers and operators is with formal assessments of knowledge and ability.

Read MoreDesign vs. Manufacturing — Can We All Just Get Along?

The relationship between these two basic departments is critical to the success of any manufacturing company.

Read MoreSecond-Referencing Variables in Custom Macro

This technique allows operators to query a large number of values using only a few CNC commands.

Read More