CNC Tech Talks

Consistency and Compatibility Improve CNC Productivity

Consistency and compatibility among CNC machines can decrease setup time and confusion among operators.

Read MoreBeyond Toolpaths: Four Additional Priorities for CNC Programs

An effective CNC program respects considerations such as ease of use and program-to-program consistency that go beyond just driving the machine in a particular application.

Read MoreNC Lessons Learned Apply to Additive Manufacturing

Just as numerical control of the 1960s had much room for growth, so do the additive manufacturing machines of today.

Read More5 Ways to Simplify Tasks for CNC Newcomers

Manufacturers can easily train new CNC users by simplifying tasks. Learn how to simplify CNC tasks for new hires in this CNC Tech Talk.

Read MoreCalling Custom Macros Through Modal Commands

While G65 does not enable users to simply and easily carry out Custom Macros in multiple locations, G66 and G66.1 provide modal solutions for doing so.

Read MoreJuggling Mismatches in Resolution and Least Input Increment

While CNC machining and turning systems of the past only had resolutions and least input increments equal to the displayed decimal places, new systems support more precise inputs.

Read MoreCustom Macros Can Skip Holes After Replacing Broken Tools

Using “vacant” local variables enables CNC machinists to create custom macros that can target multiple types of machining work.

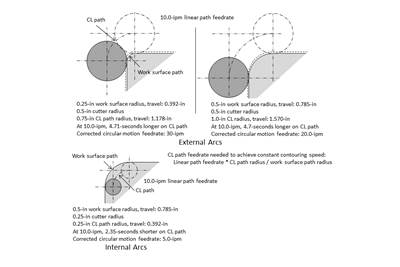

Read MoreAdjusting Feed Rate in Circular Motion Commands with G-Codes

While it is possible to calculate by hand adjustments to feed rate for circular milling operations, cutter radius compensation CNC programs streamline this process.

Read MoreHow to Modify Feed Rate for Circular Motion Commands

Maintaining a constant feed rate between linear and circular milling easily leads to chatter — for most applications, increase feed rate on external arcs and decrease it for internal.

Read MoreHow to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

Read More