Basics

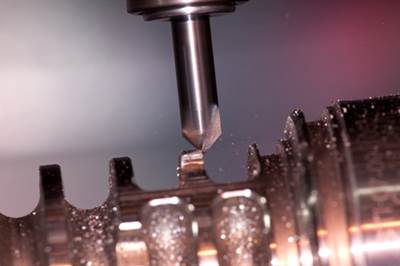

How to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

Read MoreBe Strategic With Your Holemaking Options

Just as there are a great many types of holes to be produced in today’s complex workpieces, there are a great many types of holemaking processes. Finding the right cutting tool for each holemaking application is a matter of asking the right questions and getting good answers from a cutting tool supplier.

Read MoreWhat is the Best Process for Micro-Deburring?

Various techniques address the challenge of getting a clean machined feature at microscopic scales.

Read MoreWebinar Presents Oil-Skimming Basics

Abanaki Corporation offers “Oil Skimming 102,” an online video tutorial about selecting the right oil-skimming product. The tutorial presentation is adapted from the company’s “Oil Skimming Facts Tutorial Handbook.

Read MoreThe Double-Edged Sword

There are two sides to estate planning—how to make it and how to keep it.

Read MoreWhen Less Is More: How A Class X Master Can Outperform A Class XXX

This may sound like the wrong title for a gaging column. You’d think I’d be saying something like, “when more is better,” and talking about how gage performance is improved when the gage is larger and has more mass.

Read MoreHow Much Production Run Documentation Do You Provide?

Any time you wonder why a CNC operator doesn’t know something that you think is obvious can be taken as a signal that you are not providing enough production run documentation.

Read MoreTool Pressure Deviations During Touch-Offs

How to determine program-zero assignment during touch-offs.

Read MoreUnderstanding Vacancy

Custom macro B users tend to struggle with the concept that variables can be vacant. To fully master custom macro B, you must understand the concept of vacancy and its implications.

Read MoreRigidity Required When Grinding Challenging Materials

Effective centerless grinding of hard materials requires a machine that is capable of damping process vibration at high wheel speeds and providing the rigidity to withstand very high cutting forces.

Read More