Basics

How To Machine Composites, Part 3 -- Milling Composites

Diamond shines for this shop when it mills composites.

Read MoreHow To Machine Composites, Part 4 -- Drilling Composites

Achieving acceptable tool life and hole quality in a material such as CFRP demands a drill designed with composites in mind.

Read MoreHow To Machine Composites, Part 5 -- Waterjet Cutting

For trimming composite parts, this shop describes where it uses machining centers and where it uses waterjet.

Read MoreWhy Not Ask Why?

Manufacturing can be downright instructive. The more useful concepts in manufacturing can be applied directly to our own lives. Take the distinction between roughing and finishing, for example. In manufacturing and in life, the key to effectiveness is not necessarily finesse, but knowing where the fine

Read MoreKeep The Change

Any organization that is faced with the need to change things wrestles with the questions of what to change and how to sustain that change. What to change will obviously vary from company to company and industry to industry. Often, the answer to this question is presented to us by external forces. For example, chan

Read MoreHow To Make Manufacturing Succeed

A machine shop owner turned to me for reassurance that U.S. manufacturing would remain strong. I didn’t know what to tell him. I do have confidence in U.S. manufacturing—plenty of confidence. However, that is not what he really wanted. He was concerned about his own fortunes. The problem was, the specialty machini

Read MoreSo Your Qualified Plan Is A Tax Trap - Here’s How To Escape

Do you have a significant amount of money ($400,000 or more) in one or more qualified plans—an IRA, profit-sharing plan, 401(k) or others? This is a bittersweet subject. It is bitter if you don’t know how to legally avoid the tax-robbing laws that enrich the IRS, and it’s sweet if you implement one or more of the

Read MoreCompact Handling Facility Sticks To Basics

Shops consider a number of factors when justifying automated parts storage systems, including cost, required floor space and machining application.

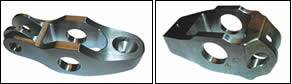

Read MoreTurning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read More

.JPG;maxWidth=400;quality=70)

.JPG;maxWidth=400;quality=70)

.JPG;maxWidth=400;quality=70)