Basics

When Pigs Fly

Makino will host a Global Titanium Day on Thursday, May 20th at its Mason, Ohio Global Titanium R&D Center.

Read MoreHow to Overcome an Acc/Dec Limitation in High Speed Machining

A small pocket in a graphite workpiece limits productivity. Part of the expert’s response is to consider how a lower feed rate might actually be more productive—because the machine will spend more time at the programmed rate.

Read MoreWhy Do Cutting Tool Charts Give Recommended Parameters in a Broad Range?

The answer has to do with the differences from cut to cut, as well as the differences that make some shops more capable than others.

Read MoreA Case for Understanding the Numbers

More often, companies are open to sharing their financial picture with their employees. Here is a brief summary of the more important financial numbers to help you understand how your company is performing.

Read MoreHow to Work a Webinar

A Webinar, in case you’ve not attended one, is an online presentation—a “Web seminar”—on a topic of interest to a specific audience.

Read MoreHow To Choose A Plasma Cutter

Contributed by Hypertherm (West Lebanon, New Hampshire). The company designs and manufactures plasma cutting systems for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes handheld and mechanized plasma systems and consumables, as well as CNC motion and height controls.

Read MoreWhen Spindle Speed is a Constraint

Though it won’t replace high speed machining, Boeing sees “low speed machining” as a viable supplement to higher-rpm machines. Using new tools and techniques, a shop’s lower-rpm machining centers can realize much more of their potential productivity in milling aluminum aircraft parts.

Read MoreLearning from Other Software Users

Some of the best ideas about how to use a product come from other users.

Read MoreHow To Become A Master Of Deviation

In the June 2009 issue, I wrote about how “less” can be “more,” by purchasing lower-grade master rings and discs and using their certified size—their master deviation—to improve the gaging process accuracy. This topic sparked a number of questions and some confusion, primarily because I did not have space to talk about actually applying this technique on the shop floor.

Read MoreWhen to Mill Keeps Changing

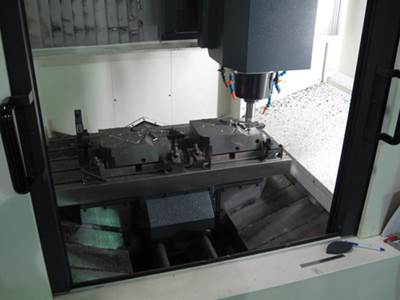

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Read More