Basics

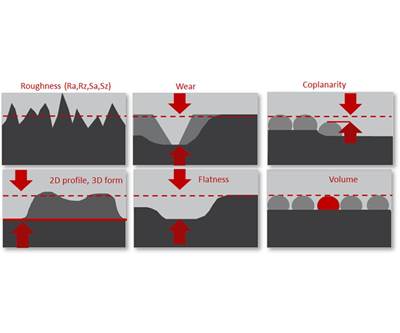

Measurement for True Surface Analysis

Optical metrology is providing more information, faster, about surfaces that were once impossible to measure and understand.

Read MoreCAM Simulation Gets Toolmaker up to Speed with B-Axis EDM

Software simulation helped this machine shop learn how to program its new advanced, high-tolerance wire EDM. The software also helped the shop turn job quotes around quickly.

Read MoreChecking Cutting Tool Offset Values

A setup program can be used to test for overtravel issues before a workpiece is run, eliminating program verification delays.

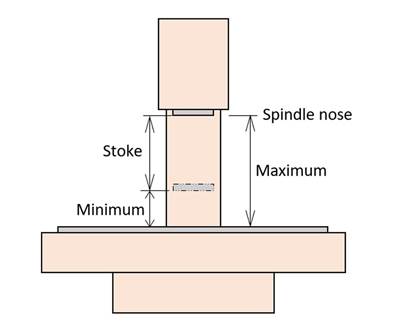

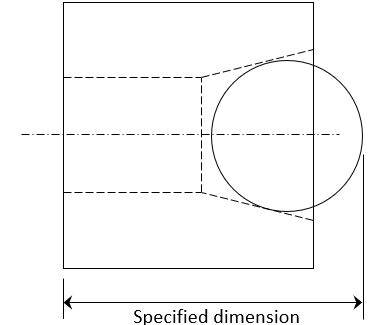

Read MoreBuying a Grinder: Latest Technological and Process Developments

Grinders have advanced in recent years with both technological and process improvements. Here is a rundown of some of those improvements.

Read MoreUnderstanding the Internet of Things

Part of the strangeness is this: There is not much to understand! Cheap sensors, fast connectivity, and data storage and applications in the cloud all come together to simplify certain kinds of automation needs. A band saw in the lab at Georgia Tech illustrates how manufacturers might put this to use.

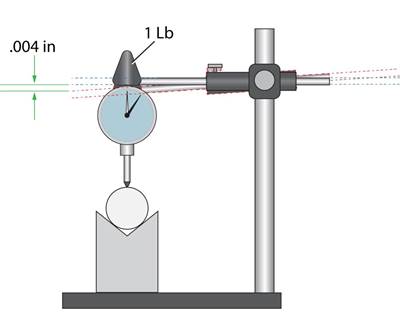

Read MoreWhy QC Inspectors Should Consider Gaging Fixture Spring Rates

All fixtures for part gaging will have some amount of deflection or spring rate that can affect measurement accuracy. A better understanding of spring rate can enable quality control inspectors to detect and eliminate this possible error source.

Read MoreWhen Machining Long Parts, Machine Shop Climate Matters

Machining long titanium tufting needle bars required a milling machine with a super-long X-axis travel. But the real challenge was thermal compensation in the Georgia heat.

Read MoreBuying a Grinder: Applications for Grinding Machines

How are grinding machines used in aerospace, medical, die/mold and other industries? Here is a rundown of some common applications.

Read MoreExternal Input for Programmed Values

Parametric programming provides three easy ways to access external data.

Read MoreBuying a Grinder: The Abrasive Process

The prospective buyer of a new grinding machine should be aware of the ins and outs of the abrasive process, how abrasive bonds work and the various forms of wheel dressing.

Read More