Basics

When a Swiss-Type Is a Lathe and a Five-Axis Mill

Swiss-type lathes with a swiveling B axis enable this shop to machine parts complete and unattended that it otherwise couldn’t using its five-axis machining centers. Here is some of what it learned adopting this new technology.

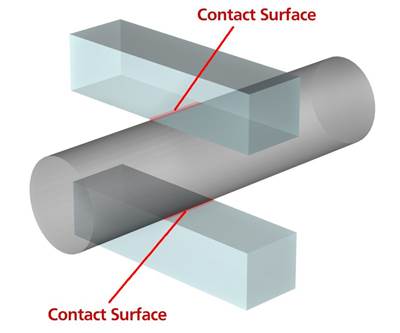

Read MoreThe Versatility of Snap Gages

The many design modifications available in snap gages enables them to measure some of the most difficult dimensions, right at the point of manufacture.

Read MoreERP Helps Forward-Thinking Manufacturers Look Back

Enterprise-wide performance data and an understanding of which metrics matter form a foundation for the predictive analytics that characterize “smart” CNC machine shops.

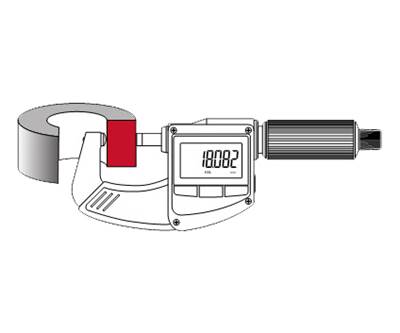

Read MoreHow to choose a micrometer that fits your needs

Match your micrometer choice to your specific machine shop needs.

Read More5 Things New CNC Machine Operators Must Know

These subjects are the building blocks of training newcomers on a specific CNC machine tool.

Read MoreTungaloy’s CeramicSpeedMill Improves Productivity When Machining HRSAs

CeramicSpeedMill, from Tungaloy, is used for milling heat-resistant superalloys (HRSAs) at elevated feeds and speeds.

Read MoreMonitoring Time for Preventive Maintenance Tasks

Not all maintenance tasks should be performed based on a calendar date. You can use a custom macro to monitor your machines.

Read More7 Tips for Programming Ceramic Cutting Tools

Ceramic tools require different thinking and a willingness to tweak tool paths developed with carbide in mind.

Read MoreThree Examples of Additive Manufacturing in Production

Is additive manufacturing (AM) ready for production scale? The latest issue of Additive Manufacturing magazine highlights manufacturers who are succeeding with 3D printing for production right now.

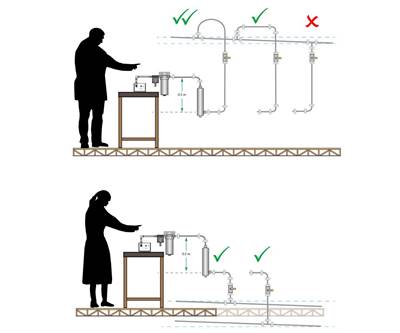

Read MoreMaintaining an Air Gage System’s High Performance

Tight, clean and dry: The requirements of air gaging aren’t very different from mechanical gaging.

Read More