Basics

Why This AM Milestone Fills the Capacity of Four CNC Lathes

Incodema3D is launching into its first continuous job to be produced with metal additive manufacturing, but more 3D printing also means more turning.

Read More3 Advantages of Using Pulsed Laser Welding for Mold Repair

Compared to TIG welding, pulsed laser-welding technology is said to enable faster overall mold repair time while maintaining higher metal hardness.

Read MoreConverting Time and Date to a More Useful Format

FANUC and FANUC-compatible CNCs have multiple ways to monitor time. They are accessed by four system variables: milliseconds clock, hours clock, current date and current time. Here’s how to format information in a helpful way.

Read MoreGrind to Finish: A Postprocessing Solution for Additive Manufacturing

3D printed metal parts typically feature little stock remaining for finishing. Grinding is potentially an effective solution for meeting final tolerances. An abrasive technology provider investigates grinding as a complement to AM.

Read MoreWhen Additive Manufacturing Goes Beyond "Manufacturing"

An additive manufacturing machine is not a direct replacement for a machine tool. Its influence potentially extends far beyond the manufacturing floor, a fact explored in the latest issue of Additive Manufacturing magazine.

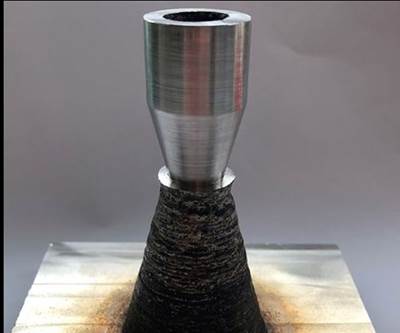

Read MoreCombining Additive and Subtractive Processes for Hybrid Machining

At this point, we are still learning how to combine the two to optimize hybrid manufacturing.

Read MoreUsing Offset Data to Determine Turret Index Position

Determine the optimal index position based on cutting tools’ current geometry offset settings.

Read MoreMeasuring Tools Basics: Faster and Better

In a high-volume production environment, the cost of inspection is related to the speed with which measurements can be made and interpreted.

Read MoreWhen Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts.

Read More