Share

The striking and important characteristic of the Internet of Things (IoT) is the way free or low-cost applications and widely available knowledge will combine to put it to work. This makes the IoT far different from automation technologies manufacturers have adopted in the past.

The free or low-cost tools include, for example, If This Then That, Twilio and Amazon Web Services (AWS) IoT—all cloud-based resources for programming automatic responses to events. With resources like these, an off-the-shelf sensor can be employed to trigger, say, an email being sent, a data point being recorded or a device being activated without any need to engineer or hardwire a system to connect the input to the response.

It is that very ease that leads to what we will soon discover to be widely available knowledge. Today’s engineering students include many who are accustomed to these tools, who play with them for their own purposes, and who therefore may accept it as a matter of course that they will use these tools in their eventual profession.

Thomas Kurfess has a perspective on this. The recently hired chief manufacturing officer at Oak Ridge National Laboratory was, until just a few months ago, the Husco/Ramirez distinguished chair in fluid power and motion control at the Georgia Institute of Technology (Georgia Tech), where he instructed students who were already becoming proficient in IoT technology.

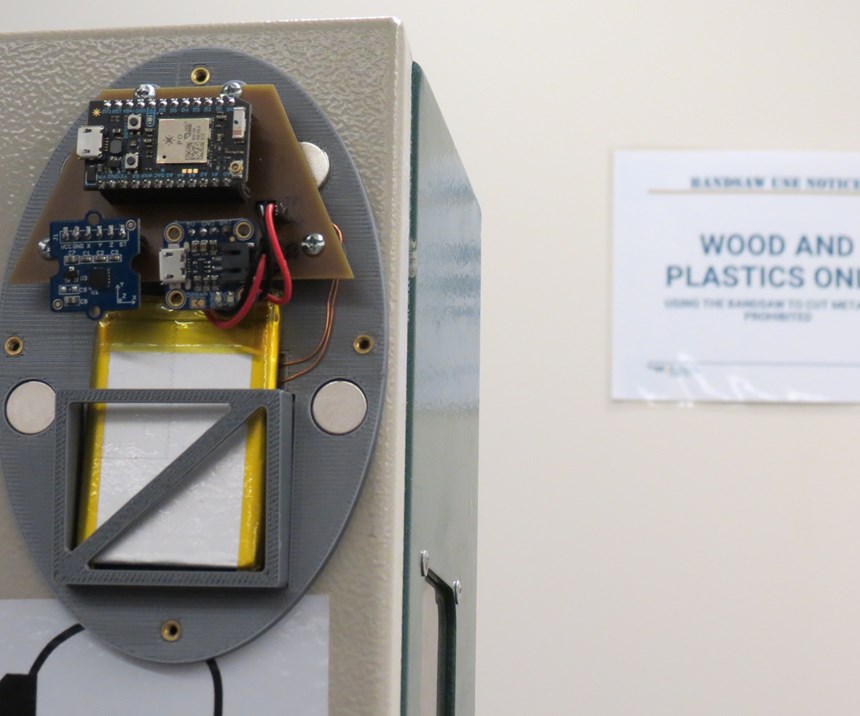

An example of that technology in use at Georgia Tech helped solve a vexing problem there: misuse of the engineering lab band saw, the most widely used and widely misused machine available to students. The saw is meant for cutting wood and plastics, but students secretly used it to cut metal all the time.

Dr. Kurfess says, “I asked some of my students if there was a way to create a system that could detect if the saw was cutting metal. They smiled and said, ‘Yes, and we can even identify what kind of metal it is cutting.’”

There was already an accelerometer affixed to the saw. It had been placed there to monitor usage patterns, but the sensor also provided sufficient data to identify rule-breakers. At Dr. Kurfess’s request, students connected this sensor via AWS to a camera in the lab and Amazon’s Alexa voice assistant unit in Dr. Kurfess’s office. Now, thanks to the logic defined using AWS, when the accelerometer measures a level of force that indicates that the band saw is cutting metal, the camera takes a photo of the vicinity of the saw to identify the saw’s user, which is then emailed to Dr. Kurfess. Meanwhile, a calculation using accelerometer data is used to compose a message spoken by Alexa that might go like this: “Excuse me, Professor Kurfess. Someone is cutting steel with a hardness of 40 to 50 Rockwell C on the ME 2110 band saw.”

This is the Internet of Things in action.

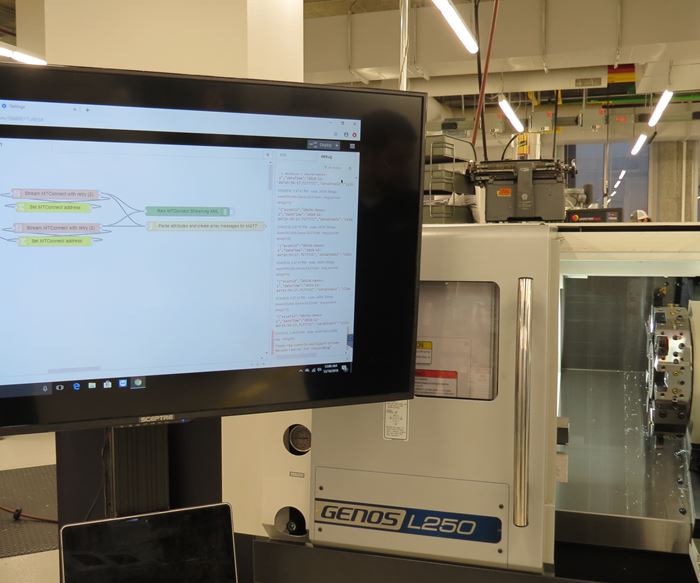

Dr. Kurfess says this application illustrates two fundamental points manufacturers ought to recognize about the IoT and what it consists of. First, its applications are comprised of these three elements: low-cost sensors, connectivity, and a data stream sent to the cloud where digital tools can process and make use of the data.

“The Internet of Things is not one development,” Dr. Kurfess says. “It’s the accumulation of these various resources coming together.” Incremental advances in all these areas—advances such as better wireless speeds and battery technology, and the multiplication of cloud-based utilities—account for why the IoT seems to have appeared suddenly without anyone inventing it.

The second point, just as important, is this: Manufacturers can take advantage of the resource this collection of elements now represents to solve some of the problems they face in production.

We already know we can do this with information tools. When there is an ongoing, recurring need for a particular data point, we can write a program or format a web page to automatically supply us with that data point and place the information where we can easily see it. The IoT represents that same simplicity applied to events and their appropriate responses. That is, without much more difficulty than constructing a custom web page to present changing data, we can construct a custom sequence of events to be triggered by changing circumstances.

“It’s all there at our fingertips,” Dr. Kurfess says. “We just have to put it together.”

An example on which he recently consulted related to coolant and lubrication levels in a production-machining facility. He says, “The worst job in the plant—the one they gave to the most junior employee—was walking around looking at all these levels. The company asked if it would be expensive to automate monitoring the fluid levels instead. We discovered the sensor needed to do this at each machine was cheaper than its dipstick.”

The company making this inquiry then understood it had asked for too little. So what about also monitoring the water temperature in the cooling tanks used for welding? Even easier, Dr. Kurfess discovered—the appropriate temperature sensors cost something like 50 cents apiece. And there was more.

“With additional sensors, we realized we could track rheometry (flow of the fluid), and also particulate count,” he says. Thus, the chore of walking around to evaluate fluids could be eliminated entirely, because an IoT application drawing on these sensors could deliver all the needed information to a central display, while also initiating corrective action such as text messages to maintenance personnel whenever a fluid quality metric falls out of specification.

Dr. Kurfess says the IoT could even be used to avoid one of the most uncomfortable developments in a machine-shop environment: the foul coolant smell.

“We could monitor coolant pH,” he says. “The pH value connects to bacteria count.” In theory, therefore, the automatic action of the Internet of Things could prevent a shop from ever having to encounter the rotten-egg odor again.Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More