Basics

Carr Lane's Hoist Eye 360 Rotates Fully When Pulling at Any Angle

Carr Lane’s Hoist Eye 360 is a forged lifting eye that can be rotated 360 degrees after installation in order to align with the pulling direction.

Read MoreAutomated Part Deburring, Cleaning in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

Read MoreAdditive Manufacturing Standards

There are gaps in published additive manufacturing standards. Here are some resources and standards to help make sense of the growing technology.

Read MoreKeeping Blanchard Grinding Current

What do you do when a large portion of your business depends on machine tools that are more than 30 years old? You roll up your sleeves and perform some of the maintenance of your machines yourself, even if you are the company’s VP, because that maintenance is crucial to the shop’s success.

Watch10 Steps to a More Organized Work Area

Workplace organization can be overwhelming. Break it into smaller steps to make it more manageable.

Read More5 Mistakes We Find in Most CNC Machine Programs

While the mistakes listed here will not sound an alarm or cause a program to fail, they will cause confusion, wasted time and scrap parts.

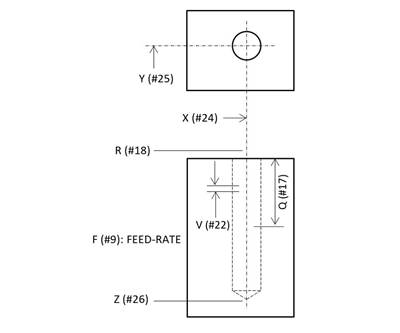

Read MoreHow to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

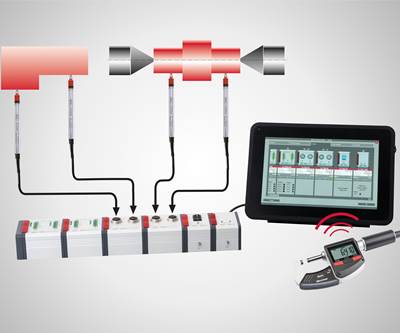

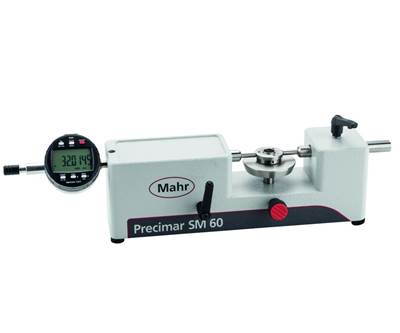

Read MoreGetting More with Digital Indicators

Today’s digital indicators are not only replacing dial indicators in some instances, but they are also approaching the performance of bench amplifiers at a fraction of the cost.

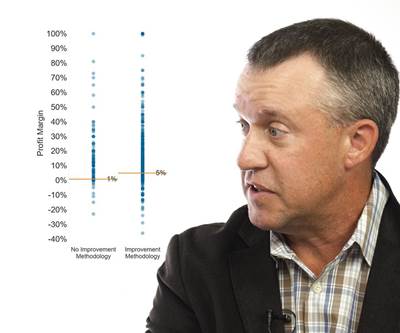

Read MoreVideo: How to Succeed at Lights-Out Machining — Findings from Top Shops Data

Differences in machine shops’ profit margins suggest the value of improvement methodology, unattended machining and machine tool monitoring, as well as the effective combination of all three of these.

Watch