How to choose a micrometer that fits your needs

Match your micrometer choice to your specific machine shop needs.

Share

A micrometer consists of two opposing surfaces, a stationary anvil and a moveable spindle. On most micrometers, these hardened steel or carbide-tipped contact surfaces are flat. However, micrometers can also be equipped with contact tips with unique forms for measuring special part characteristics.

Convenience is one of the reasons the micrometer is often the tool of choice for length/diameter measurements. The basic micrometer provides direct size information quickly, has high resolution and is easily adaptable to many different measurement applications. In addition, today’s electronic technology provides fast, easy readings and the potential to collect the results. Beyond the basic flat anvil micrometer, there are a variety of micrometer types that extend these advantages to many special measurement applications.

The optimal micrometer choice depends on your specific needs.

Do you need faster measurements?

All micrometers employ a rotating thimble, and most use a screw drive to move a rotating spindle. Because the screw drive is the basis for the measuring system, it has to be a fine pitch – typically 0.025 inch/0.5 millimeter. If a user is measuring a part with multiple diameters within the range of the micrometer, a lot of effort is put into turning the thimble to adjust the spindle from one size to the next.

However, newer digital micrometers are not dependent on a screw thread as its measuring system but rather an independent, electronic scale. Therefore, the driving of the spindle is independent from the thimble, and a courser thread drive can be used, which can result in a 5 to 10 times improvement of measuring speed. This also comes with the benefit of a sliding spindle that is great for measuring compressible materials and essential for blade contacts, as follows.

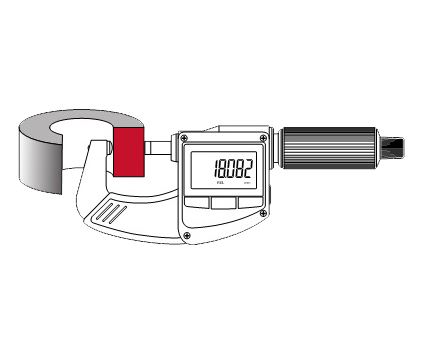

Do you need to measure a groove?

Measuring the outside diameter of a cylindrical part from inside a turned groove on its surface calls for another type of micrometer contact blade. Often these grooves can be so narrow that neither a standard nor reduced-face micrometer will fit completely into the groove. Blade contacts, as the name implies, are very slender and flat. They nest readily into narrow-bottomed grooves.

The blade solution created an interesting problem for the blade micrometer's designer. The spindle surface of most micrometers rotates as the micrometer barrel is turned, but a blade inside a groove will eventually be constrained from rotating. So, blade micrometers have a spindle that slides along the axis of movement instead of rotating. Using this style micrometer calls for greater care. As always, check to make sure the micrometer is on the true diameter. Also, check frequently for wear on the measuring surfaces. Because the ends of the blades are so narrow, there is very little measuring surface. Excessive pressure on these narrow blades, as the tool is being rocked to find the true diameter, can result in premature wear.

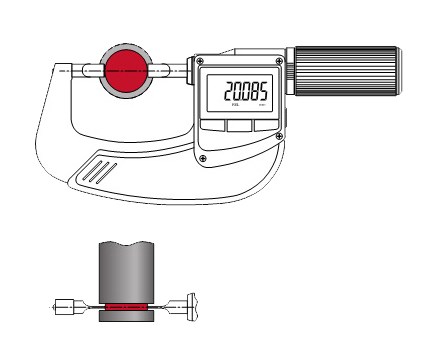

Do you need to know a tube’s wall thickness?

Ball contacts are used to measure wall thickness of tubes and other cylindrical components. Micrometers are available with one- or two-ball/radiused contacts. The one-ball/radius style may be used for inspection of wall thickness on tubing.

Two-ball/radius contacts can inspect thickness between holes. In some cases, the ball contacts can be supplied as attachments for use with a standard flat-tipped micrometer. The attachments may be quickly and easily applied to either the anvil, the spindle or both. When using this type of attachment, the ball diameters must be taken into account by subtracting them from the micrometer reading.

Do you need to measure a narrow land?

Reduced spindle style micrometers have a turned down diameter on both the anvil and spindle. These contacts are used to measure inside recesses where the normal diameter may be too wide to penetrate. Because the contact areas of the anvil and spindle are very small, these micrometers may take a little getting used to. To get the proper "feel," take care to make sure the face of each contact is square with the axis of the diameter being measured.

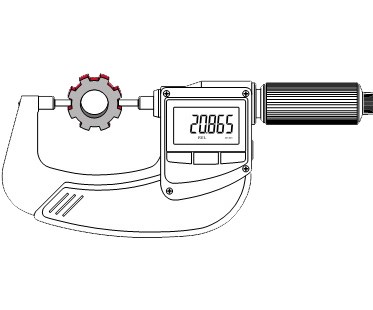

Do you need to know the width of a tooth?

On the same part, measuring the distance between the grooves is accomplished with a disk micrometer designed for thickness measurements on features that have narrow clearances. The measurement contacts are relatively large disk-like flats that extend beyond the diameter spindle and anvil. Because these contacts have such a broad measuring surface, parallelism errors can creep into the measurement. Therefore, it is important to check parallelism of the contacts using a precision ball on many locations between the contact faces. A discrepancy of more than a grade of the Vernier scale is a sign that the parallelism of the anvil and spindle needs to be corrected.

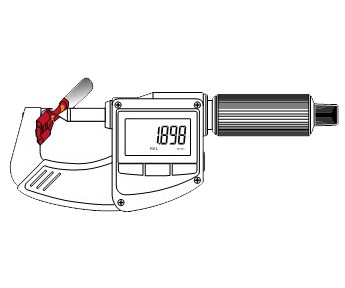

Do you need to know how big a splice is?

Have a crimp or bend in sheet metal and need to know its thickness or if it’s a spliced wire and connector? A micrometer with a narrow land as a reference and a point on the spindle provide a good point to line measurement for these applications.

Even the best and most basic hand measuring tool can be made better by adapting it to special application requirements. By choosing the most appropriate style of the application, you will achieve a faster and more accurate measurement. Each style, however, has its own unique requirements for care and use. If you're going to measure with style, make sure you know how to do it properly.

Related Content

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

Measuring Tools Basics: Faster and Better

In a high-volume production environment, the cost of inspection is related to the speed with which measurements can be made and interpreted.

Read MoreMaintaining an Air Gage System’s High Performance

Tight, clean and dry: The requirements of air gaging aren’t very different from mechanical gaging.

Read MoreMeasurement for True Surface Analysis

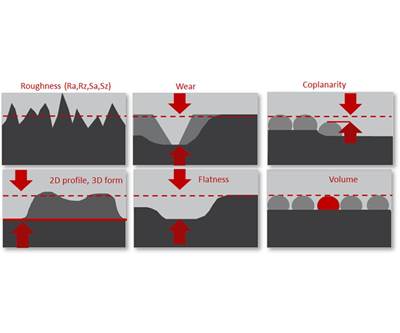

Optical metrology is providing more information, faster, about surfaces that were once impossible to measure and understand.

Read More