Share

A turret option is available to accommodate as many as five waterjet deburring tools for complex parts. Tool geometry can be optimized via metal 3D printing.

Cleaning specifications can be more stringent for hydraulic and pneumatic components, automotive transmission components, pump and valve housings, nozzles and so on. Burrs, swarf or debris left behind after machining or grinding parts like these can lead to product failure during use, which is why secondary finishing processes are often necessary prior to assembly.

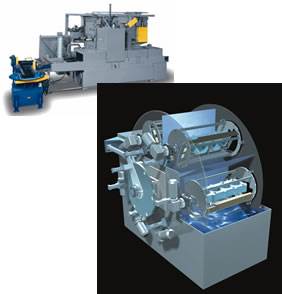

Traditionally, multiple pieces of equipment —sometimes from multiple suppliers — have been required to perform all the necessary finishing work. However, as I saw at the EMO trade show in Hannover last September, the EcoCvelox from Ecoclean combines high-pressure waterjet deburring (in five axes) with low-pressure parts cleaning and drying in one compact unit. This eliminates the need to use various equipment suppliers, and a modular design enables future expansion as needed.

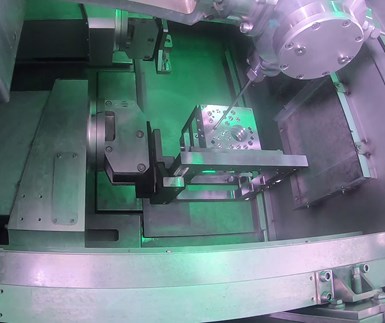

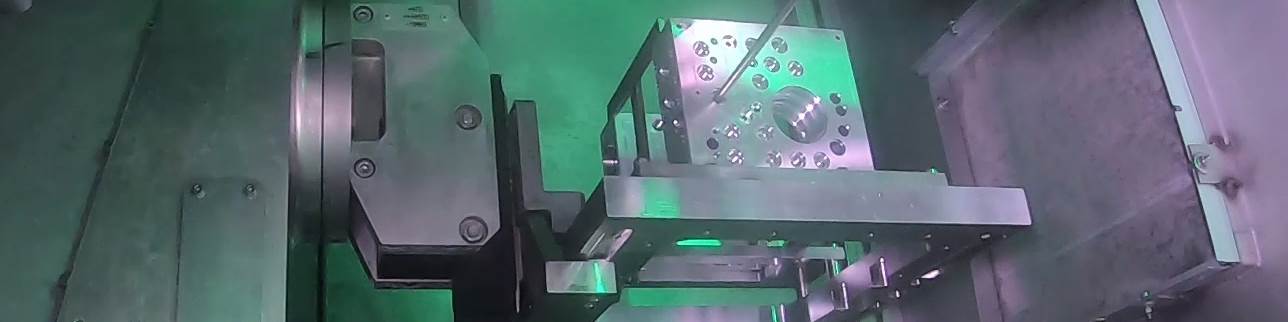

As seen from above, an indexer facilitates five-axis waterjet deburring. (Photo: Ecoclean)

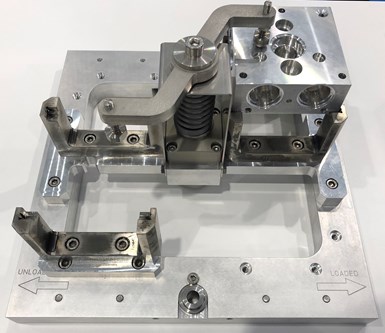

Parts as heavy as 10 kg and large as 200 by 200 by 200 mm are fixtured on pallets that are delivered manually or via robot or gantry loader to the deburring station. (It is possible to design pallets to accept multiple, smaller parts.) Pallets are installed on the deburring station’s B-axis indexing table, orienting features to be deburred with respect to a waterjet tool. A single waterjet tool exerts 1,000 bar of pressure, though 3,000 bar is available as an option. For more difficult deburring options, a turret can accommodate as many as five tools, with tool-to-tool indexing time of 1.5 seconds.

Pallets can accept parts measuring 200 by 200 by 200 mm. Multiple, smaller parts can be fixtured in that working envelope, too.

A range of tool geometry is possible. In fact, the company can optimize tool design by manufacturing them with a metal 3D printer. Programming the deburring operation can be done at the machine’s control or offline using CAD/CAM software. The latter is particularly helpful for complex parts. A camera system can also be integrated into the deburring station for part identification/verification.

The standard EcoCvelox system features one Y-axis pallet-handling unit for the deburring station. For higher throughput, a second pallet-handling unit can be integrated.

A linear-drive motion system moves the pallet with the deburred part(s) at a rate of 5 meters per second to the cleaning station for injection flood washing, spray and selective rinsing, or a combination of cleaning processes. A high-velocity air blow-off and/or vacuum dries the part(s).

Programming for the deburring operation can be performed offline using CAD/CAM software.

Tool wear (pressure drop) is inherent to waterjet deburring, leading to tool replacement after a given number of operating hours. The EcoCvelox is said to offer 50% longer tool life thanks to its operating software and a variable-frequency-drive-controlled, high-pressure pump that readjusts waterjet pressure levels to adapt for tool wear.

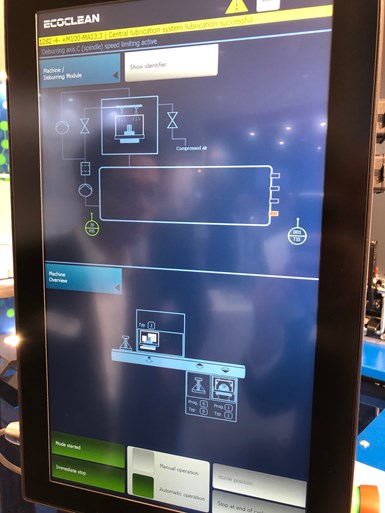

A touchscreen control presents color-coded system components so operators can see their status at a glance.

The system’s control features a tablet-like, 19-inch touchscreen monitor (HMI) in which all system components are graphically represented with color codes that display their current operational states. Operators can touch the image of a given component to access digital documentation such as flow or electrical circuit diagrams as well as lists of spare parts to speed part order and delivery.

Related Content

Madison Chemical Degreaser Easily Removes Machining Oil

ProClean Degreaser quickly and completely removes oil and grease with its superior wetting and penetrating properties.

Read MoreAlliance Manufacturing's Cleaning Systems Use Safe Solvents

PMTS: The company’s vacuum degreasing machines use solvents to remove contaminants from manufactured parts without the use of water or scrubbing.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreNMP's Parts Cleaning Systems Pass Upcoming Regulations

PMTS 2023: ITF Parts Washing Equipment machines are designed to help prepare and sustain manufacturers for the upcoming environmental regulations in North America.

Read MoreRead Next

Precision Cleaning: An Introduction

Many manufacturers today are coming to cleaning for the first time.

Read MoreHow Clean Is "Precision" Clean?

Specially engineered aqueous cleaning equipment is normally necessary to obtain the cleanliness levels automakers demand. There are general system attributes that a precision cleaning system should possess.

Read MoreSlideshow: Faster Cleaning & Deburring

Conveyor integration and other time-saving features are common amongst the products covered in this month’s slideshow.

Read More

.png;maxWidth=300;quality=90)