Video: How to Succeed at Lights-Out Machining — Findings from Top Shops Data

Differences in machine shops’ profit margins suggest the value of improvement methodology, unattended machining and machine tool monitoring, as well as the effective combination of all three of these.

Share

The success machine shops increasingly are having today with lights-out machining is the result of various advances that have come together: more systemized processes plus more accessible automation technology plus machine tool monitoring. After reading my recent article describing this point, Steve Kline of Gardner Intelligence reached out to share that he sees corroboration for the combined effectiveness of these advances in the data resulting from our annual Top Shops benchmarking survey. Looking at differences in machine shops’ profit margins, he sees evidence not only for the value of a shop employing (1) an improvement methodology, (2) unattended machining and (3) machine monitoring, but also for a logical pathway from one to the next to the next.

In this video, Steve Kline and I discuss the Top Shops data and what it suggests about choices shops might make that contribute to lights-out machining.

Transcript

Peter Zelinski, Modern Machine Shop

Pete Zelinski with Modern Machine Shop magazine. I'm here with Steve Kline of Gardner Intelligence. So I'm the writer. Steve's the researcher. Welcome, Steve.

Steve Kline, Gardner Intelligence

Thank you, Pete.

Peter Zelinski

I've been thinking a lot about lights-out machining. I think that lights-out machining is a very important development in metalworking — more important than we appreciate. There have always been some facilities that were capable of running lights-out, running unattended for an extended period time through the nighttime hours. It is becoming more common now, a lot more common. There is process discipline. You know, the move years ago toward lean manufacturing was sort of the beginning of this. And then there is greater use of and greater confidence in unattended machining, thanks to automation technology becoming more economical, more accessible. And then the piece that is the most recent is machine monitoring. I say all that because you've heard me talk about that, and you've looked at our Top Shops data and found some conclusions in that data that validate that picture. So first Top Shops. What is our Top Shops survey? Where does this data come from? What's that all about?

Steve Kline

So Top Shops is Modern Machine Shop’s Modern Machine Shopannual benchmarking survey that Gardner Intelligence conducts for . Every year, shops answer a whole range of questions on their machining practices, the machine technology they have, HR practices and business strategies. There are about 30 numerical questions that we ask and then a couple hundred yes-or-no-type questions that we ask as well. Then we score shops on those questions and determine the top 20% of scores — our Top Shops for that year. Then we compare them to the other 80% of shops. One of the valuable things shops get out of that is a customized report that shows where they're strong, on which metrics they're doing really well, where they're sort of in the middle of the pack and where they have areas for improvement. Over the last nine years, we've had more than 3,000 unique shops participate in that survey.

Peter Zelinski

So another value that we're realizing is the ability to look at that body of data and find correlations that tell us things. Particularly, you've been looking at the effect of different variables on profit margin, and it speaks to what we're talking about here.

Steve Kline

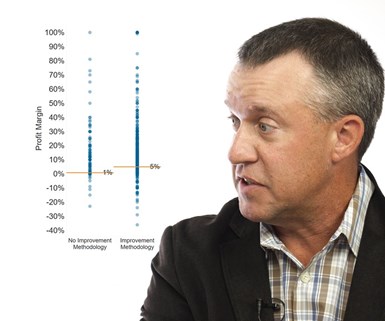

Yeah. So as soon as I read your column, I instantly said I can go to the Top Shops data, and I bet I can find something that verifies what you were seeing anecdotally over the years in shops. When we look at improvement methodology, we ask about 16 different improvement methodologies in the survey. So I wanted to see if a shop is using any one of those 16, and what is their profit margin versus the shops that aren't using an improvement methodology. In the chart we're looking at here, we have about 1,100 shops that have either answered yes to having an improvement methodology or no, I don't do any one of those 16. About 85% have an improvement methodology, and about 15% don't. But we see a pretty stark difference in the profit margin in that the shops that have an improvement methodology have a median profit margin represented by the orange line on the chart of 5% versus those that don't have an improvement methodology of just 1%. So a fairly significant difference. In looking at all the data, this really seemed to be the foundational point in the three developments that you were talking about, that had the biggest difference in profit margin.

Peter Zelinski

So if we if we accept improvement methodology as a basis and then we add to that shops that are doing unattended machining thanks to automation technology, what further incremental impact does that have?

Steve Kline

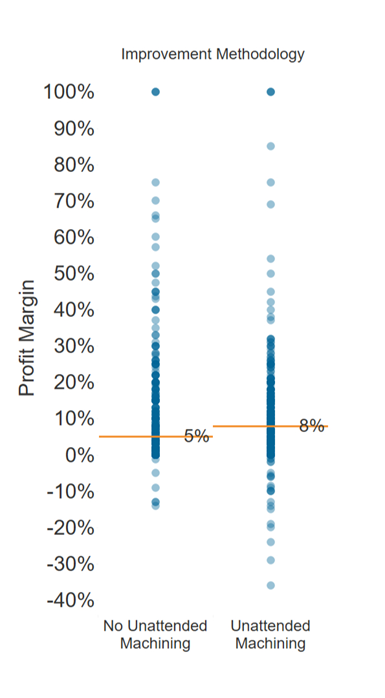

So it was really interesting when we layered on unattended machining to the improvement methodology. One of the things that we saw is that when you aren't doing an improvement methodology, those 15% of shops that weren't, they're very unlikely to do unattended machining. The addition of unattended machining for the few that did it had virtually no impact on their profit margin. Basically, everybody stayed at a zero to 1% profit margin. So it was really the combination of the two things — an improvement methodology and unattended machining — that provided the difference. When we look at the chart here, we see that there's still a difference in those shops that have an improvement methodology but don't do unattended machining versus those that do. So the ones that don't do unattended machining, their profit margin stayed at 5%, but the ones that do unattended machining, their profit margin jumps by 3 percentage points up to 8%. So almost a 50% increase in their profit margin by adding unattended machining on top of their improvement methodology.

Peter Zelinski

OK, so then we're going to keep on laddering on the variables. So the next step is machine monitoring. How does the graph we're looking at now show even more profit margin gain as a result of adding machine monitoring?

Steve Kline

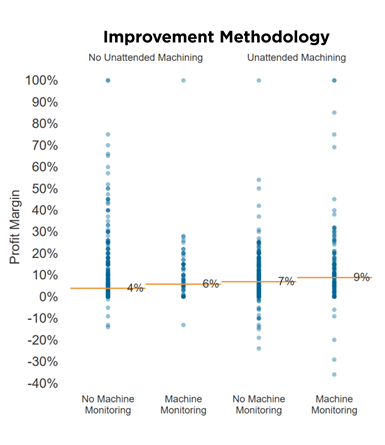

So it's really interesting when you add that on top of it. We're going to leave out the shops that don't do an improvement methodology here because there's so few of them that don't do an improvement methodology but somehow do unattended machining or have a machine monitoring system. It's just very uncommon practice. So if we look at all the shops that do an improvement methodology, we had about 750. If we start with those that don't do unattended machining and don't do machine monitoring, we see that their profit margin is about 4%. So actually a little less than all the shops that have an improvement methodology of 5%. So some of that improvement methodology profit margin that we saw of 5% we know is coming from these other factors of unattended machining and machine monitoring. And then we can move to shops that do an improvement methodology, don't do unattended machining, but have machine monitoring systems. We see a little bit of an improvement in profit margin from 4% to 6%. But we notice that there's relatively few shops that do that that are able to skip the second step in the three developments of unattended machining. It's really rare to go from improvement methodology to machine condition monitoring. And then we can look at those shops that have an improvement methodology and do practice unattended in machining, but don't do machine condition monitoring or machine monitoring in general. We see a bit of an improvement in the profit margin there, up from 6% to 7%. So you're better off doing an improvement methodology and unattended machining and not machine monitoring than having an improvement methodology and not unattended machining and machine monitoring. Right? There's an order that these things need to be done. But the best performance came from the shops that have an improvement methodology, have layered on unattended machining and then have layered on top of that a machine monitoring system and their profit margin jumps to 9%. So it's really interesting if we think about that middle step of unattended machining. Right? If you don't do it and you're doing the other two things, your profit margin is 6%. But if you have the middle step of unattended machining and are doing the other two things, your profit margin jumps up to 9%. So, you know, 50% increase. So one of the things I saw in the data that helped us see the order of these is that the difference in profit margin of improvement methodology or not was 4%. The difference in profit margin of unattended machining or not was about 3%. Then the difference in profit margin between machine monitoring and not was about 2%. So each one of these layers on this extra level of profit margin.

Peter Zelinski

Lights-out machining. It is a journey. There are steps on that journey and the steps are undertaken in a specific order. But if profit margin is a proxy for success, which I think we could argue it's a pretty good proxy, then the potential value of following those steps toward getting to an effective, reliable lights-out machining process — the value is there. The value is measurable. We can see it in our data.

Steve Kline

Yeah. And I think there's lots of other things we can correlate with profit margin as well. So hopefully we'll be sharing more of that with you as we come across ore interesting topics in your columns.

Peter Zelinski

Very cool. Stay tuned.

Related Content

Job Shops Can’t Do Everything, And That’s OK

Deciding to narrow down its jobs and customers was a turning point for 2023 Top Shops Business Strategies honoree Manda Machine that has led to improvements in the front office and on the shop floor.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreTop Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreRead Next

Running Unattended at Night Lets Machine Shop Serve New Customers During Day

Precision Tool Technologies found capacity for diversification not by adding machines, people or space, but by freeing up time. Running unattended—running so it can machine through all 168 hours in the week—has enabled this shop to use hours when staff is present to deliver work that lands outside its established specialty. To achieve unattended machining, some of the biggest challenges have related to basic details such as chips and coolant.

Read More3 Mindset Changes for Lights-Out CNC Machining

Expanding capacity into the unattended hours calls for counterintuitive new ways of thinking about the work.

Read MoreMerging Advances: Lights-Out Machining Combines Automation and Focused Process Improvement

One of the most significant developments in machining right now is easy to miss because it is the union of two different advances coming together.

Read More