Basics

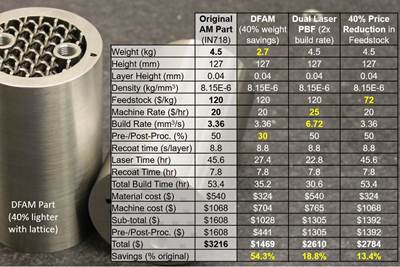

The Value of Design for Additive Manufacturing (DFAM)

Design is the “value multiplier” when it comes to additive manufacturing.

Read More5 Tips for Selecting the Optimal Spindle Range

Learn how to select the appropriate spindle range and ensure that your CNC machining center or turning center is running an optimized cycle.

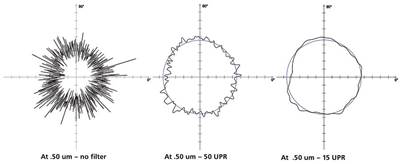

Read MoreTips for Choosing Filter Settings When Measuring Round Shapes

When interpreting measurement data, the correct filter setting is necessary to see the difference between surface roughness and part roundness.

Read More3 Reasons Machine Shops are Paying Attention to ERP

Awareness of people and the value of their efforts accounts for part of the reason why we are seeing enterprise resource planning being taken more seriously.

Read MorePractical Approaches to Automation

Automation isn't just useful for large volumes of the same part. Today, it is increasingly being used in machine shops for high-mix, low-volume jobs.

Watch5 Best Practices for Manufacturing Cybersecurity

A Department of Defense (DoD) push to protect data by vetting suppliers more thoroughly illuminates how any CNC machining business can improve.

Read MoreAutomating the Indicator Calibration Process

Eliminate human error when calibrating precision hand tools by leveraging modern vision systems.

Read MoreHow to Choose the Best Drill Type for Your Next Job

Five questions to ask when deciding between solid carbide drills or replaceable insert.

Watch3 Ways to Improve CNC Utilization Without Sacrificing Safety

Operator safety is the most important consideration when improving CNC machine utilization.

Read MoreParts Cleaning Conference Webinar Series Begins Oct. 7

The 2020 Parts Cleaning Conference educates the industry with a webinar series, offering five presentations from leading manufacturing cleaning companies. Find out how to register.

Read More