Basics

First Steps to a Connected Machine Shop (Big Data for Small Shops)

In this demo, Renishaw demonstrates how connecting an older style CNC to a PC tablet directly over ethernet, can empower machine tool operators to immediately become more productive. (Sponsored)

WatchPreparing SQC For Machinists and Future Requirements

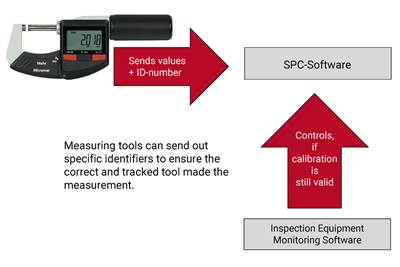

The current complexity of machines means machinists are already busy — assigning them new, expanded SQL duties (such as gage identification) will require gages and processes to prioritize accessibility.

Read MoreIs Wireless Data Collection a Cultural Choice?

Untethered digital inspection tools are easier to justify for those who are willing to hold themselves accountable and improve for improvement’s sake.

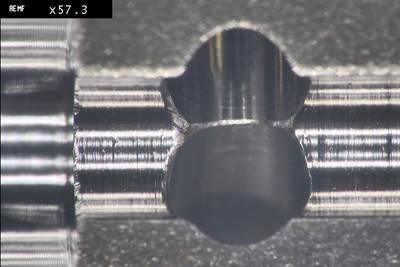

Read MoreCross-hole Deburring Tool Eliminates Secondary Process

The Orbitool from J.W. Done helped Paramount Machine eliminate a secondary deburring process, saving 75 process hours across a 2000-part run and enabling the shop to meet its profit and delivery time goals.

Read MoreCalling Custom Macros Through Modal Commands

While G65 does not enable users to simply and easily carry out Custom Macros in multiple locations, G66 and G66.1 provide modal solutions for doing so.

Read MoreReal Work Through the Xometry Partner Network, No Quoting Required, Free to Join, and New Jobs Added Daily

In this Digital Demo, Xometry’s Partner Success Manager guides machinists through the company’s Partner Network, highlighting how to become a partner; finding work through the partner portal; and the benefits of being a Xometry Manufacturing Partner. (Sponsored)

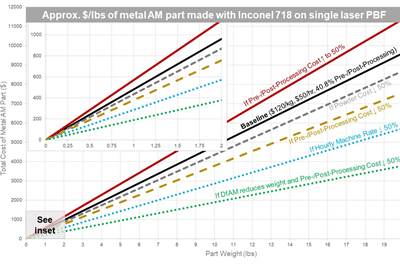

WatchPlotting a Pathway to Profitable Additive Manufacturing

The cost per pound for a metal AM part may be shocking, but that knowledge is essential to plan a journey to success with Additive Manufacturing.

Read MoreHow to Successfully Transition from Dial Indicators to Digital

Digital indicators bring a wealth of benefits over dial indicators, but simply swapping one for the other can lead to problems in repeatability and process durability.

Read MoreReal Examples of 3D Printing in the Automotive Industry

3D printed end-use parts are going onto vehicles with increasing frequency. Recent real-world examples showcase additive manufacturing benefits in design, weight savings and more.

Read MoreJuggling Mismatches in Resolution and Least Input Increment

While CNC machining and turning systems of the past only had resolutions and least input increments equal to the displayed decimal places, new systems support more precise inputs.

Read More