Basics

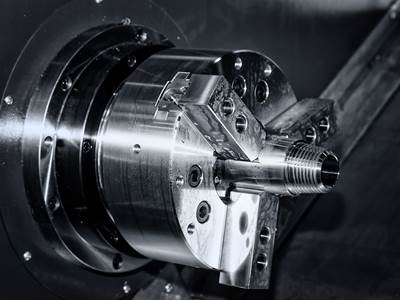

How to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

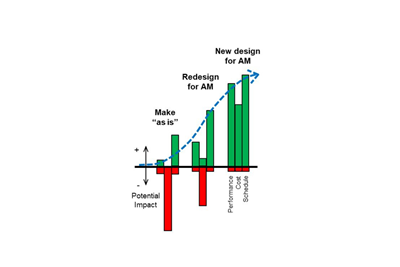

Read MoreHow Do Binder Jetting and Multi-Laser Powder Bed Fusion Match Up?

Both metal 3D printing processes are ready for production, but which wins out for speed and cost? Research from The Barnes Global Advisors offers a case study.

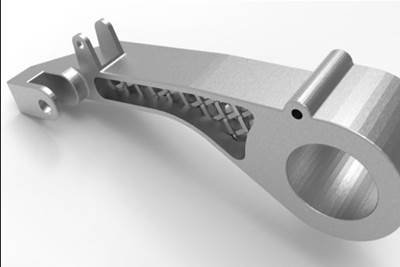

Read MoreBeginning the AM Journey: An Uphill Battle

Faster machines, cheaper feedstocks, new standards — with all of these advances, why is additive manufacturing still “an uphill battle” for so many?

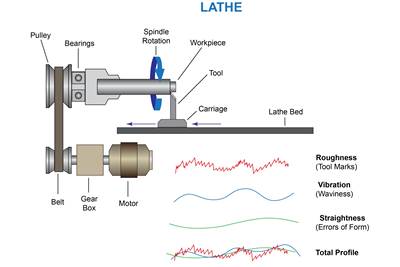

Read MoreWhat to Know About Decoding Surface Finish Gages and Parameters

Long-wavelength waviness and short-wavelength roughness require a wide variety of instruments and parameters for proper measurement — and lower numbers aren’t always better.

Read MoreStarting with the End in Mind: An Exit Strategy for Machine Shops

John Shegda and Eric Wilhelm each had different ideas about how they wanted to phase into retirement. The exit strategies for the three successful manufacturing businesses the two men operated included a mix of seeking equity groups, selling the business, or transitioning into an employee stock ownership plan. All it took was a friendly suggestion from a mutual friend to set them on a different path.

Read MoreHow to Match Thickness Gage Types to Proper Applications

Different thicknesses require different gage types during inspection — four common ones are handheld indicators, handheld micrometers, opposed air streams and gage blocks.

Read MoreWebinar | Automated CNC Machine Setup for the Smart Factory

Learn how to maximize the value of your CNC equipment through automated setup with Jon Caliguri of DSI.

Read MoreChoose the Correct ID/OD Gage for the Task

Benchtop and portable comparator gages each have their place, but the differences are more than surface deep.

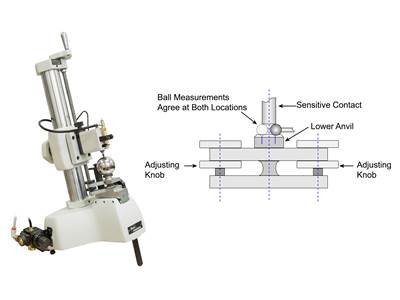

Read MoreConfirming Dimensional Accuracy of a Precision Ball

A single diameter isn’t the only measurement parameter that can be used to ensure accuracy.

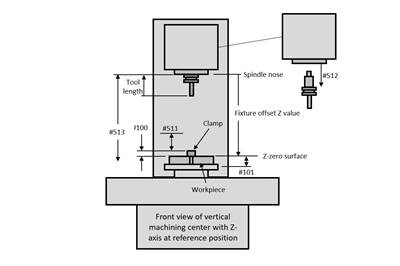

Read MoreT Codes Simplify Tool Length Confirmation Process

CNC users can program custom macros and T codes to ensure cutting tools are the proper length for tool length compensation in machining centers.

Read More