Share

Metal 3D printing is gaining ground in production applications, with two methods that stand out in particular: binder jetting and multi-laser powder bed fusion (PBF). Both promise to deliver geometric freedom, speed and cost savings for the right metal parts. But how do these two processes measure up?

John Barnes, creator of The Barnes Global Advisors additive manufacturing consultancy group, has been exploring this dynamic in a series of articles over at Additive Manufacturing Media. The complete trilogy covers the benefits of multi-laser PBF and the business case for these systems, in addition to how they compare to binder jet 3D printing. Below, we’ll focus just on that comparison in terms of speed and cost — but be sure to check out the full series for greater detail.

Binder Jetting

Metal binder jet processing (BJP) is a form of 3D printing that uses fine droplets of binder to hold metal powder together. The binding agent is precisely deposited on the powder bed to form each layer of the part. In some cases, such as sand 3D printing, the printed piece is considered complete. But for metals, the as-printed shapes are considered “green” parts. A sintering step is necessary to fuse the powder together into a dense metal part.

Binder jetting has the advantage of being a “cold” 3D printing process, which avoids creating residual stresses in the parts and eliminates the need for support structures. Parts can be stacked in the Z axis as well as the X-Y orientation, making it possible to print many parts at once and sinter them in large batches.

Multi-Laser Powder Bed Fusion

Powder bed fusion also builds parts layer by layer from powder, but with the use of a laser or electron beam to melt the material during the printing process. As-printed PBF parts are effectively dense after printing, although they may require heat treatment afterward. In the past few years there has been a trend toward incorporating multiple lasers into these systems, allowing PBF printers to build larger parts or many parts at once more quickly. (Recently introduced PBF printers are equipped with eight and twelve lasers, for instance.)

Powder bed fusion supports greater geometric complexity in the final parts, and the use of an energy source to densify the powder during printing may reduce the amount of post-print processing over binder jetting. Multi-laser systems can speed the point-by-point sintering process so that layers can be completed faster.

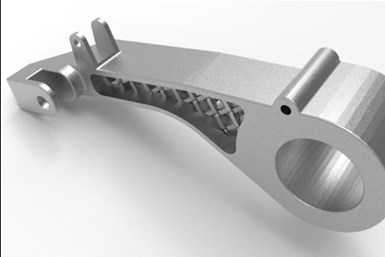

The Barnes Global Advisors devised this control arm to be suitable for both binder jet and powder bed fusion processing. Image Credits: The Barnes Global Advisors

Often, the geometry and size of a given part will lend itself to one process over the other. But for the sake of investigation, The Barnes Global Advisors devised a control arm that could be suitable for either process as a basis to compare them in terms of print speed, effective print speed (the full process time it takes to make the print useful) and part cost. The results of this comparison are below.

Speed and Cost

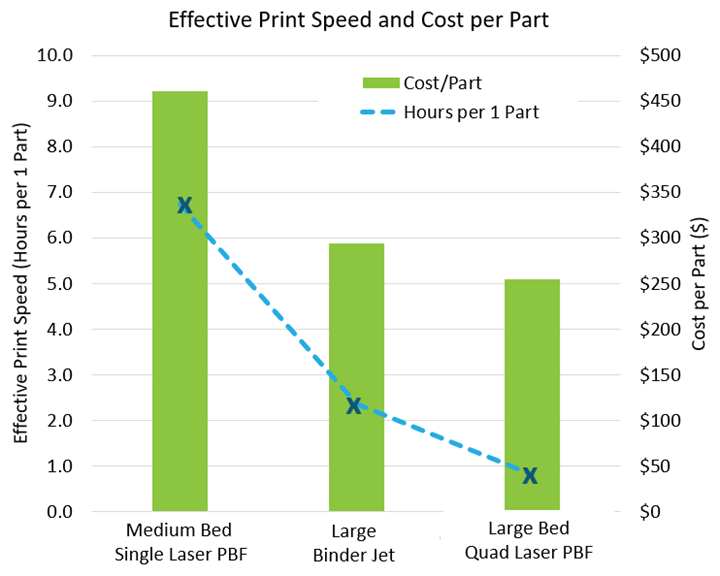

As the graph below shows, it would be possible to produce more control arms per build through binder jetting versus powder bed fusion, but quad-laser PBF can deliver parts more quickly. When the effective print speed is taken into account, binder jetting is the slowest process even though its literal print speed is less than that of a single-laser PBF process.

The second part of the study was to evaluate the projected cost of the part on each platform. Results are shown below. In this case, the large-format quad-laser PBF system resulted in the lowest cost per part, though both multi-laser powder bed fusion and binder jetting offered cost savings over single-laser PBF.

For more on the details of this comparison and additional information on multi-laser powder bed fusion, see the original posts on AdditiveManufacturing.Media:

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read More6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreHow to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreRead Next

What This Golf Club Says about Reshoring Manufacturing

This putter showcases the possibilities of metal additive manufacturing for design and product development, but also production closer to home.

Read MoreAfter the Build Is Done Why Do the Bills Keep Coming?

When your additively manufactured part is done printing, you just pull it out of the machine and start using it, right? Not even close.

Read MoreIndustrializing AM: A Simple Cost Equation

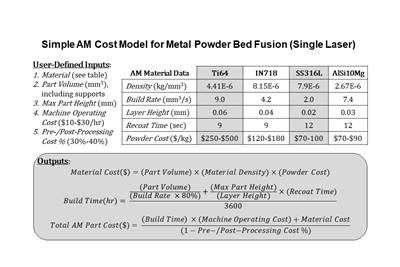

The costs of AM are still throttling its adoption.

Read More

.jpg;width=70;height=70;mode=crop)