Beginning the AM Journey: An Uphill Battle

Faster machines, cheaper feedstocks, new standards — with all of these advances, why is additive manufacturing still “an uphill battle” for so many?

Share

Despite faster machines, cheaper feedstock and new standards, additive manufacturing (AM) is still “an uphill battle” for many. While limitations in AM technology remain (feedstock and machine operating cost, build speed and part quality challenges), there is still a way to chart a course and begin the AM journey. In fact, I wrote about it last month. Asking how design for manufacturing can help save weight, integrate functions, add internal features, engineer surfaces, tailor materials and improve agility will help with that journey and shine light on AM’s value. It will not be easy, but by and through design, organizations — not equipment or powder suppliers — are in control of the value AM. Yes, they still control powder pricing and dictate operating costs, but combining design’s dual role of adding value while avoiding costs is key to reaching that first peak and seeing new opportunities for AM that may be on the horizon.

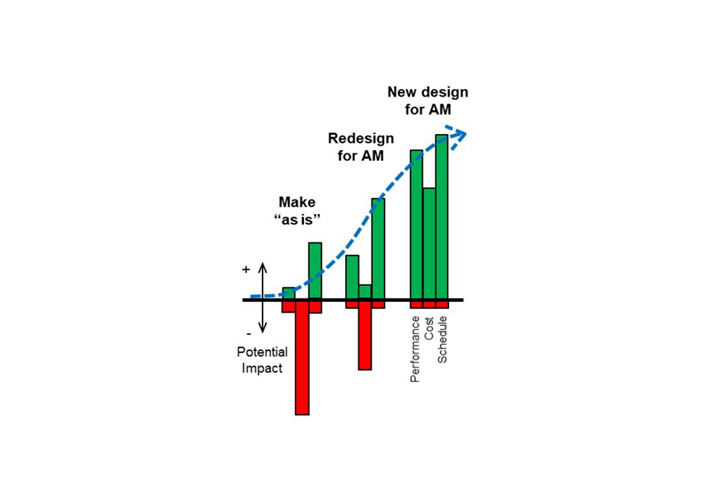

Notional diagram of the potential impact of AM on performance, cost, and schedule as a company progresses on their journey. Photo Credit: Tim Simpson

So why the uphill battle? It largely happens because the tendency is to begin with AM as a process substitution, reproducing an existing part made via conventional means with AM. The performance and cost benefits of AM are often in the red. The only benefit at this first step is speed, but it is for a part that has already been designed, so shortening the product development cycle for an existing part doesn’t really help. The trick then is to find situations, such as spares and repairs, in which speed reduces lead time.

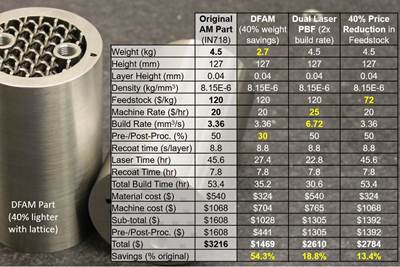

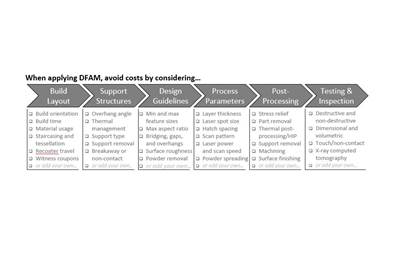

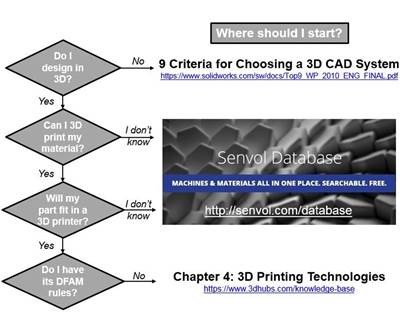

To gain traction with AM and begin the uphill climb, consider modifying the part, or MfAM as I now call it (thanks David Dietrich and the team at Honeywell for bringing this to my attention). MfAM is a succinct way to avoid the unwanted costs of AM that I discussed last month, and its application is just as important as the more exciting things that people talk about when designing for AM (e.g., topology optimization, lattice designs, biomimicry, and such) as I discussed two months ago. Unfortunately, the full freedom to apply design for AM (DfAM) may not be possible until somebody can “clean sheet” a part or completely rethink an existing part for AM. Few established firms begin there, and they have to endure the earlier stages and chart an uphill course to maximize AM’s benefits.

The uncertainty around the potential upside of future parts designed for and made with AM clouds this view, making the journey all the more difficult. Add the baggage one carries when basing the initial AM business case on process substitution that simply reproduces an existing part with AM, and it is clear why it is an uphill battle. The benefits often don’t add up, weighing one down from the start. Worse, it can derail the AM journey entirely as the costs add up.

But there is hope, as DfAM and MfAM are the “ying and yang” of a successful AM journey. DfAM drives value while MfAM avoids costs, and both are critical to making AM viable.

When redesigning a part for AM, begin with MfAM and apply DfAM to the best extent possible. Conversely, when designing a new part from scratch, begin with DfAM and apply MfAM to reduce costs. Not surprisingly, the end points from each of these endeavors is not the same, nor is the starting point. As such, the benefits differ as well. MfAM improves producibility and viability with AM, advancing one up the hill on their initial journey. As the path forward becomes clear, DfAM increases the benefits and helps one reach the peak. From there, the horizon comes into much better view. Fighting the uphill battle is worth it when looking back on all that has been learned along the way.

Related Content

What are Harmonics in Milling?

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreHow to Optimize Operator Efficiency on Any Shop Floor

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

The Value of Design for Additive Manufacturing (DFAM)

Design is the “value multiplier” when it comes to additive manufacturing.

Read MoreAvoiding Costs while Adding Value with DFAM

Design for Additive Manufacturing (DFAM) is as much about finding value as it is about avoiding costs with AM.

Read MoreWhere Do I Start with AM?

Here are a few more basic questions to ask yourself before diving in.

Read More