Aerospace

A Two-Speed Approach To Plunge Roughing

In plunge roughing, the strategy is in the stepover. Here is a plunge roughing strategy that has worked well for Boeing researchers.

Read MoreThinking Big

This shop specifies large machine tools for the machining possibilities of the future. To prepare for the feed rates the shop expects to use one day, the latest large gantry mills apply linear motors on all three linear axes.

Read MoreAerospace OEMs Back A Lean Sea Change

A lean enterprise initiative comprised of aerospace primes and their suppliers, attempts to bring commonality to the supply chain. Its strategy is to provide a gage to measure lean progress and a roadmap to the higher levels of process maturity.

Read MoreWhy Boeing Is Big On Right-Size Machine Tools

Simple, dedicated machines save on capital expense, while they also make it possible to realize one-piece flow. These machines are often developed internally. 'Chaku-chaku' is the new ideal.

Read MoreTools For Titanium

With all of the titanium that will be required for a new aircraft, any of 1,000 spindles might benefit from the tools and techniques described here.

Read MoreWhen Probing Is Pivotal

Software for using the probe at angles expands the productive capabilities of this plant’s five-axis machine.

Read MoreMachining Centers Reconsidered

A stable customer relationship gave this shop the chance to fundamentally change its equipment.

Read MoreOptimize Cutting Efficiency, Optimize Throughput

A machining process based on maximizing cutting efficiency, rather than speeds and feeds, offers aerospace component manufacturers an option to high speed machining when high material removal rates are required. The best strategy may be to apply both machining concepts.

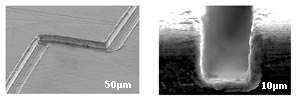

Read MoreMachining Under The Microscope

Sandia National Laboratories experiments with turning and milling tools just 10 and 20 microns in size.

Read More