Machining Under The Microscope

Sandia National Laboratories experiments with turning and milling tools just 10 and 20 microns in size.

Share

Though the term "micro machining" gets applied to just about any machining work that is performed on an unusually small scale, researchers at Sandia National Laboratories (Albuquerque, New Mexico) tend to avoid the term for their own small-scale milling and turning.

To them, the prefix "micro" implies the ability to generate features down to a single micron in size. This is something they can't do—at least not with milling and turning. Sandia's tools are better suited to generating features that are at least 25 microns in size.

In other words, though they may shy from saying "micro machining," the work here comes closer "micro" than that of almost any other metalcutting shop.

Meso-machining is what these researchers say instead. The tiny milling and turning tools are made by sculpting carbide and HSS blanks using a focused ion beam.

End mills made in this way can be as small as about 20 microns in diameter. Turning tools can be about 10 microns wide. This type of tooling is what is needed for meso-machining, because when it comes to the machine tool, appropriate technology already exists.

Therein lies one of the more surprising aspects of Sandia's work. Though experimental cutting tools had to be developed, experimental machine tools are not a requirement for using them. The researchers use these tools effectively on precision machine tools that are available from commercial suppliers.

The primary reason for the meso-machining research relates to nuclear weapons. Gilbert Benavides, Sandia manufacturing engineering department manager, explains the connection. He says existing nuclear weapons have components that are sometimes replaced, and ideally those components can be improved upon. However, each component has a fixed size and shape, because the components around it in the assembly won't change. Therefore, the only option for adding new features is to compress more features into existing spaces. Meso-machining might provide a means to do that.

Exactly what new features might be added to nuclear weapons is left to the imagination, but here is a selection of additional details on Sandia's meso-machining work.

Capabilities

Sandia has become proficient at milling slots between 20 and 30 microns wide in materials including aluminum, brass and 4340 steel. A typical depth of cut is 1 micron. One test in aluminum using a carbide, two-edge, 22-micron-diameter end mill at 1-micron depth of cut and 18,000 rpm showed that this tool could perform effectively at feed rates up to 50 mm per minute. This tool milled without fracture (across a varying feed rate) for longer than 6 hours.

The turning tools have proven durable as well. One representative test showed a 13-micron-wide tool able to cut a 4-micron-deep helical groove in aluminum over a total length (if the groove was unwound) of 200 mm.

The Tools

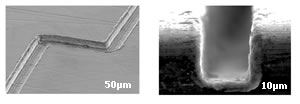

Turning tools resemble their full-size counterparts. Milling tools do not. When shaping tools with an ion beam, there is no way to generate the fluted, complex geometry that is typical of a standard end mill. Instead, meso-machining end mills have simple geometric cross sections, as photos on these pages show.

Do the tiny tools really cut in the same way that full-size cutters do? The answer appears to be yes. Observation of meso-milling with an optical microscope has shown what appear to be chips ejected from the vicinity of the tool. In addition, electron microscope inspection of milled parts reveals cutter marks.

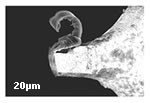

The evidence is even clearer in turning. Just as with full-size turning tools, the meso-turning tools are sometimes discovered to have stringing chips still attached to them after cutting.

The Machines

Milling tests described above were performed on a Boston Digital machining center purchased in the 1990s. The 1-micron resolution of this machine made it possible to position a tiny tool relative to the work by "touching off" in the same way that a machinist might use a manual milling machine. That is, the researchers kept jogging down, micron after micron, until the appearance of what looked like a chip (seen through a microscope) told them the tool must have made contact with the part.

More recent milling work has been done on a precision machining center from Willemin-Macodel. Meso-turning work is done on a diamond turning machine from Moore Tool, though Sandia uses tool materials other than diamond. The shop also generates small features through EDM, using wire and sinker machines from Agie. (And to complete the picture, laser machining is another area of meso-machining research here.)

Some Challenges

At present, meso-turning is more practical than meso-milling, says Mr. Benavides. With milling, the inability to replicate a conventional end mill form is just one of the limitations. Another is the difficulty of indicating the tool in the toolholder to a level of runout small enough to be acceptable for a 20-micron cutter.

Then there is the lack of demand. Sandia's customers have yet to ask for work that might require a milling tool smaller than 130 microns (0.005 inch). For features such as tiny external gear teeth, the shop would be inclined to use wire EDM. However, if internal gear teeth were ever needed, then meso-milling might be required.

Meso-machining technology Minimum feature size and feature tolerance Material removal rate in cubic microns per sec. Materials

Focused ion beam (used to make cutting tools) 200 nanometers, with

tolerance of 20 nanometers 0.5 Any

Milling or turning 25 microns (10 microns in turning in some cases), with tolerance of 2 microns 10,400 Aluminum, brass, mild steel, PMMA

(a plastic)

EDM 25 microns, with tolerance of 3 microns

25 million Conductive materials

But research continues into the various meso-machining methods, milling included. To get around the problem of toolholding and the associated runout in milling, Sandia is experimenting with a custom spindle that rotates the tool without any need for a toolholder. Developed at the University of Florida, this spindle is capable of 500,000 rpm. (For more about the spindle, see "Learn More.")

A more general challenge affecting meso-machining is the level of specialized knowledge necessary to make it work. These cuts are not like macro-scale processes, where tools, parts and programs can be run interchangeably from machine to machine. Meso-scale cutting requires an operator who understands how different tiny errors stack up under different circumstances, and how the precision of a particular machine is affected by particular choices of parameters such as speed and feed rate. It can take months of trial and error for a skilled machinist to acquire this understanding, Mr. Benavides says. The need for this understanding imposes a restraint on how broadly meso-machining can be applied. Even among Sandia's 50 or 60 skilled machinists, he says, only a handful have had the time to become adept at this work.

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreRead Next

Micro Milling At 1/2 Million RPM

Researchers aim to develop a spindle that accounts for the differences between macro and micro machining.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)