Aerospace

Empowering The Programmer

A project aimed at making military aircraft parts faster shows just how much productivity gain can come from automating the programmer's repetitive tasks.

Read MoreStart With Waterjet For More Effective Milling

For aircraft components machined out of plate stock, this shop roughs with abrasive waterjet before finishing with conventional milling. Removing roughing from the machining center cuts cost and lead time.

Read MoreBetter HSM For Big Parts

'High speed machining' is accepted and commonplace in many shops. HSM is so widely used, in fact, that its acceptance is beginning to affect the design of machine tools.

Read MorePreventative Maintenance Programs Head Off Downtime Before It Starts

In today's intense marketplace, the conventional wisdom of don't fix it if it isn't broken no longer prevails as major manufacturers realize they cannot afford sudden misalignment and unplanned downtime with their major machine tools.

Read MoreMachine Tool Coolant Racing To Save Time And Improve Quality

As a former racecar driver, Jon Horgas is well aware that raw horsepower alone does not guarantee victory, and the fastest car does not always finish first. It takes a combination of finely tuned aerodynamics and suspension, fuel mixtures and gear ratios, driver skills and experience, a top-notch pit crew, tire composition, high quality components, and luck.

Read MoreGetting The Time Out Of Titanium

For Boeing engineers successful at high speed machining of aluminum, the next step is to mill faster in a more constraining metal.

Read MoreMachining Center Meets The Production Needs Of The Aerospace Industry

Today, Metalcraft is recognized throughout the aerospace industry as one of the foremost manufacturers of complex structural components and integrated assemblies. The company has built thousands of airframe assemblies and details for the top aerospace companies.

Read MoreProcess Reduces Cycle Time For Aircraft Blade Refurbishment

The refurbishment of aircraft engine turbine blades is important to aircraft owners and operators because of the high original cost of the component.

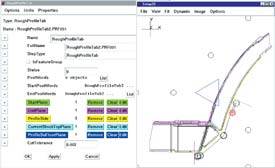

Read MoreProgram Configures Complex Fixtures

Klune Industries is a $30-million, 170-employee job shop that produces products such as bomb racks, missile sections and numerous other complex structural components for both military and commercial aerospace applications.

Read MoreBuying Metals On The Internet

Using the Internet to shop for and purchase metal stock can be efficient and safe. The advice offered here applies to all online buying.

Read More

.jpg;maxWidth=300;quality=90)