Columns

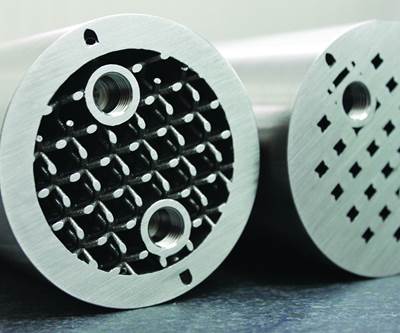

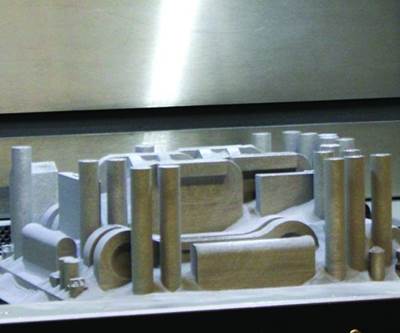

Lightweighting with Lattices

Instead of building components as a solid, building them as a network of unit cells may improve material utilization and performance.

Read MoreWe Are Investing in the Print Magazine

We are doing so because our audience is there. Some findings suggest that’s not likely to change soon.

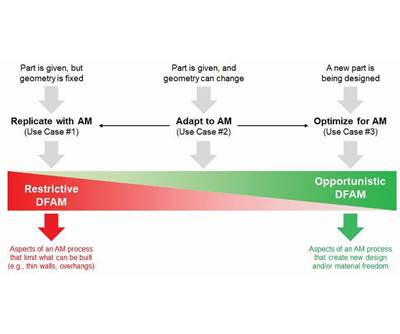

Read MoreManufacturing for Design, Not the Other Way Around

AM allows us to make any shape we want, without having to adapt the design for the manufacturing process.

Read MoreTracking Time with Custom Macro

System variables allow for time-based applications like tool-life monitoring, preventive maintenance, sampling inspections and machine warm-up.

Read MoreWhat to Know About Surface Finish Measurement

Texture is viewed differently by different manufacturing professionals, but the parameters for describing it are standard.

Read MoreThe Effect of Lot Size on Productivity

The more parts to be produced, the more elaborate the manufacturing process. Here are some other important considerations that can impact productivity.

Read MoreA Checklist for Gaging Devices

Don’t assume your gage is correct just because it has a calibration sticker. If it hasn’t been in frequent use, follow a measurement checklist to make sure.

Read MoreAre U.S. Machine Shops Choosing to Stay Small for the Long Haul?

Spending plans offer a clue to the new way shops plan to expand their output.

Read MoreFunctional Prototyping

Using AM rather than conventional methods offers companies speed and flexibility.

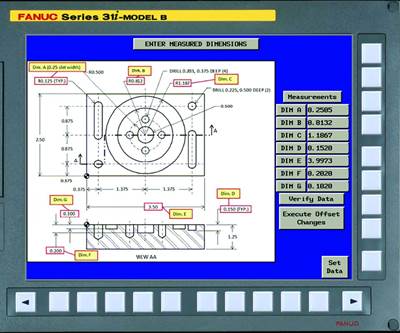

Read MoreControlling Your CNC Display Screens

CNC manufacturers have begun offering programs that allow end users to customize how display screen pages look and work.

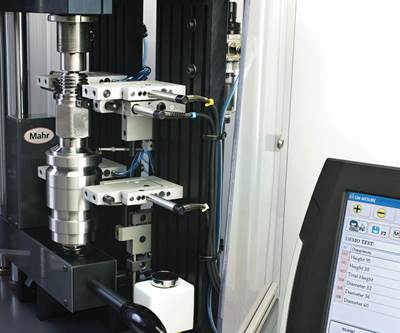

Read MoreHow Gaging Flexibility Saves Time and Effort

A gaging system that matches the way parts are made can save you both time and effort.

Read MoreAre AM Parts as Strong?

The technology’s use for replacement of a flight-critical part says they are.

Read More