Columns

Data Collection for Industry 4.0

Wireless technology is moving onto the shop floor, and its integration in digital gaging is contributing to the next Industrial Revolution.

Read MoreThe Arrival of Low-Cost Metal AM?

Systems just introduced promise to lower the price of entry for 3D printing metal parts.

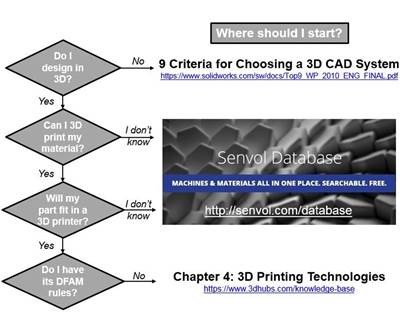

Read MoreWhere Do I Start with AM?

Here are a few more basic questions to ask yourself before diving in.

Read More4 CNC Shop Practices That Hurt Productivity

Stop employing these four common CNC shop practices to make better use of employee and machining time.

Read MoreWhat to Know About Roughness Average

Roughness average, the most commonly used parameter for surface finish, is a good starting point for quantifying parts when there is no parameter callout.

Read MoreTheory and Practice of the Shop Visit

There is certain information that can only come from standing in the facility.

Read MoreTrade-offs with AM

Current design tools and process workflow are inadequate to meet our needs.

Read MoreWhat are the Benefits of Variable Gaging?

Although more expensive, gages are a better solution than measuring instruments for higher-volume production runs and tighter tolerances.

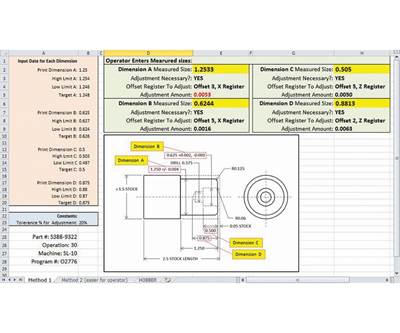

Read MoreMobile Spreadsheets for Sizing Adjustments

This is one area in which operators often struggle, so provide a reference tool to make the job easier.

Read MoreKeep an Eye on AI

Big data is just the beginning. In the future, optimizing the system will be a function of the system itself.

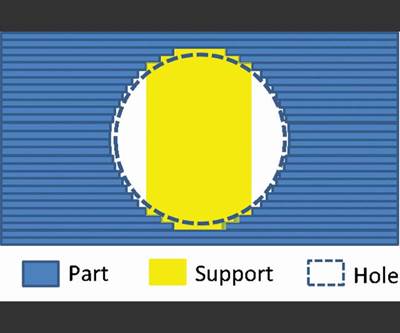

Read MoreWhy Are Holes Circular?

Geometries that are easy to machine may not be easy to fabricate additively.

Read MoreIdentifying Machines from Within CNC Programs

The technique outlined here offers a seamless way for a single CNC program to be used when a job is run across different machines.

Read More