Columns

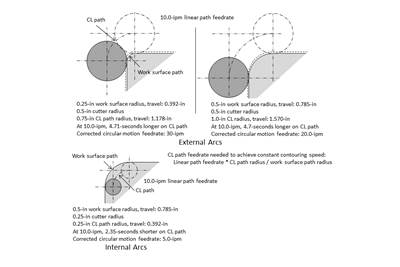

How to Modify Feed Rate for Circular Motion Commands

Maintaining a constant feed rate between linear and circular milling easily leads to chatter — for most applications, increase feed rate on external arcs and decrease it for internal.

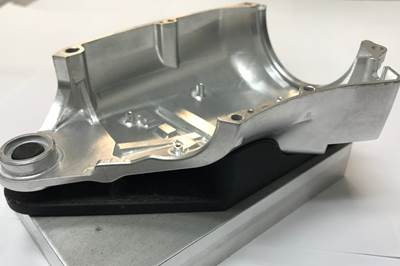

Read MoreFive 3D Printing Trends Mirrored in Machining

The underlying drivers of additive manufacturing’s advance are increasingly easy to spot on automated CNC machine shop floors.

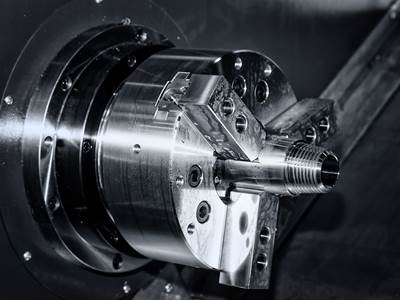

Read MoreHow to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

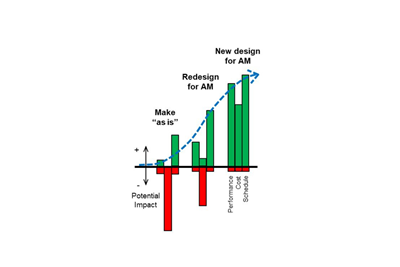

Read MoreBeginning the AM Journey: An Uphill Battle

Faster machines, cheaper feedstocks, new standards — with all of these advances, why is additive manufacturing still “an uphill battle” for so many?

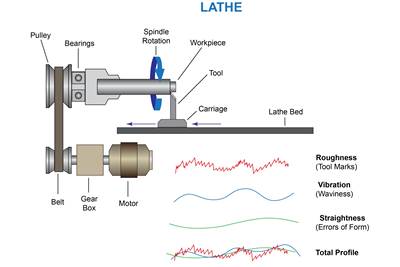

Read MoreWhat to Know About Decoding Surface Finish Gages and Parameters

Long-wavelength waviness and short-wavelength roughness require a wide variety of instruments and parameters for proper measurement — and lower numbers aren’t always better.

Read MoreIntroducing Our New Podcast, “Made in the USA”: The Show for This Moment in U.S. Manufacturing

Join us as we talk about jobs, the supply chain, generational transition and other important themes that will shape the way forward for U.S. manufacturing. Hosted by Modern Machine Shop editors Brent Donaldson and me.

Read MoreHow to Match Thickness Gage Types to Proper Applications

Different thicknesses require different gage types during inspection — four common ones are handheld indicators, handheld micrometers, opposed air streams and gage blocks.

Read MoreManufacturing E-Commerce Expands with Expectations

Whether by automating on their own terms or joining a vetted network, manufacturers are responding to demand for easy online part ordering.

Read MoreChoose the Correct ID/OD Gage for the Task

Benchtop and portable comparator gages each have their place, but the differences are more than surface deep.

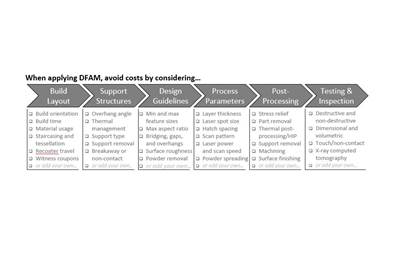

Read MoreAvoiding Costs while Adding Value with DFAM

Design for Additive Manufacturing (DFAM) is as much about finding value as it is about avoiding costs with AM.

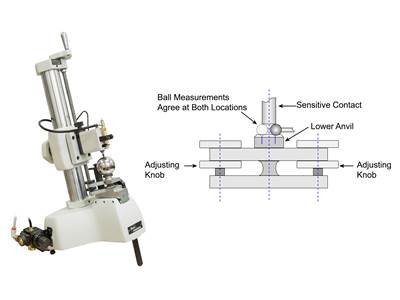

Read MoreConfirming Dimensional Accuracy of a Precision Ball

A single diameter isn’t the only measurement parameter that can be used to ensure accuracy.

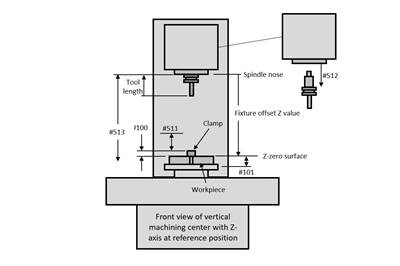

Read MoreT Codes Simplify Tool Length Confirmation Process

CNC users can program custom macros and T codes to ensure cutting tools are the proper length for tool length compensation in machining centers.

Read More