Steady as She Goes

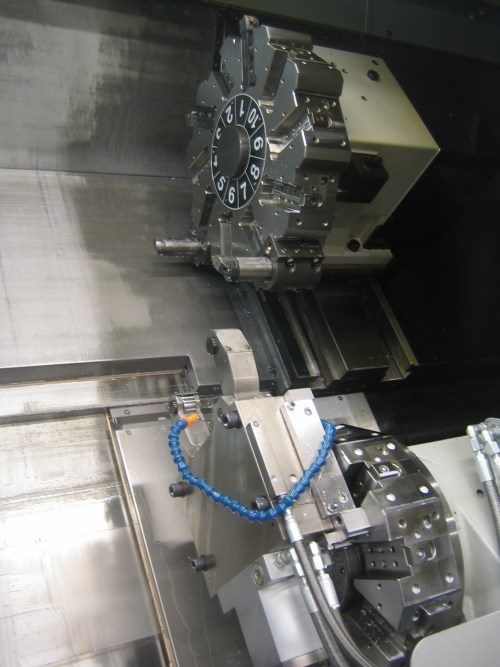

Machine shops are inventive operations. Learn how one uses a steady rest in a different way on one of its two-turret CNC lathes.

Share

That shop’s owner offered a candid take on turn-mills, by the way. Integrating turn-mills was one of the most challenging endeavors his shop undertook (but he’s certainly glad they did it). Learn more in this article.

Related Content

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

.jpg;maxWidth=300;quality=90)