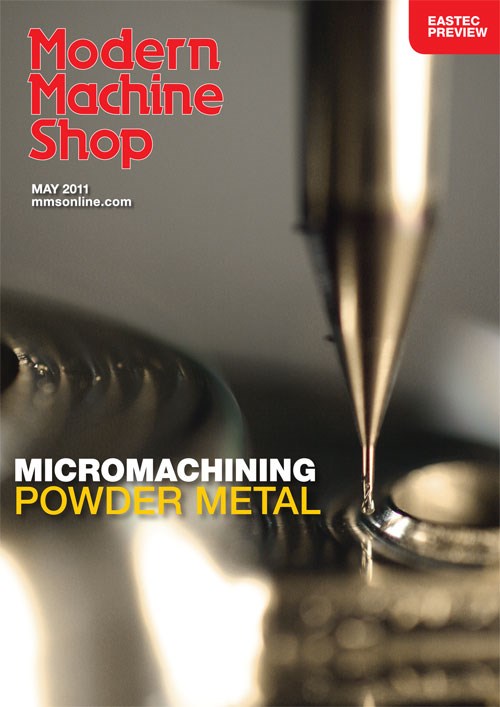

Micromachining and Flat-Screen TVs

A Pennsylvania shop has benefitted by developing an effective micromachining strategy for hard tooling components. Learn more about this as well as the interesting incentive program it’s implemented.

Share

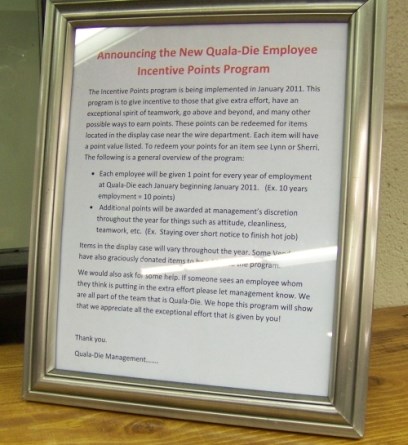

And here’s another example of the type of neat tidbits we learn about because we actually take time to visit shops. This year, Quala-Die implemented an incentive points program to reward employees who give extra effort.

Employees build points that can be redeemed for items like the ones shown below. Send me an email if you have implemented a similar program. I’d love to hear about it.

Related Content

-

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

.jpg;maxWidth=300;quality=90)