MMS Blog

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

WatchDigital Demo: People and History Drive Solutions

Bourn & Koch has long provided unique manufacturing solutions. However, the people who work at Bourn & Koch enable the company to deliver value to each partner they work with. From service to assembly to engineering, each step builds on the solution—helping you solve your most challenging manufacturing problems. (Sponsored)

WatchStart From Here: Build Up Your Mega Factory

Smart technology is all about the digital enablement of production equipment for better process control, data intelligence, IoT and more.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreFive Areas of CNC Machining to Simplify With G Code

Optimizing G code to make CNC setup and operation simpler is a great way to improve CNC productivity and sometimes prevent errors.

Read MoreWhen Too Many Customers Spoil the Part

Duo CNC used to take on as many customers as the shop could handle. But when growth stalled, a top-down audit by the company’s general manager revealed that its customer base was inhibiting growth — and causing the shop to be less efficient and productive.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreFive Safety Considerations for CNC Machinists

Safety in CNC environments is essential for users – and for productivity. Consider these 5 points to avoid injury, part failure and downtime.

Read MoreIMTS 2022 Review: Attention to Automation Extends Beyond the Robot and the Machine

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

Read MoreMetalworking Growth Stays Consistent in August

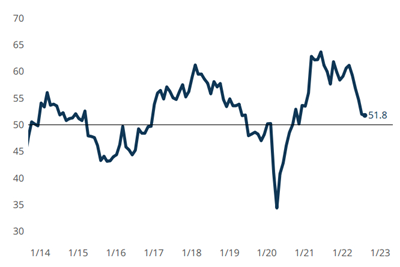

All components of metalworking activity contributed to the consistent slowdown in the past few months.

Read MorePositioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

Read MoreHow Automation Keeps Quality Control in Control

Collaborative robots help inspection keep pace with machining in a custom, digitalized workflow for complex aerospace and defense parts.

Read More