MMS Blog

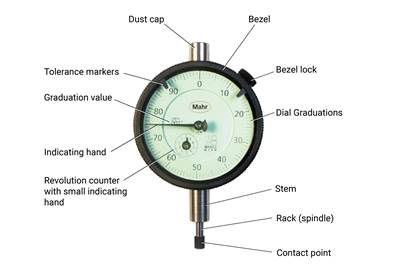

Reading What the Dial Indicator Is Saying

Dial indicators provide good value for their resolution. With a glance, one can quickly determine if the part is larger or smaller than the master setting and by a degree of how much.

Read MoreSolving Process Issues With a Detail-Oriented Approach

It is essential for a machinist and a shop to have the discipline to pause a process and reassess when encountering issues, even when schedules are tight.

Read More7 CNC Parameters You Should Know

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized.

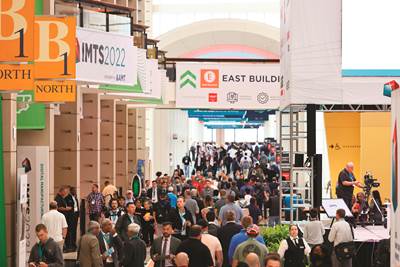

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

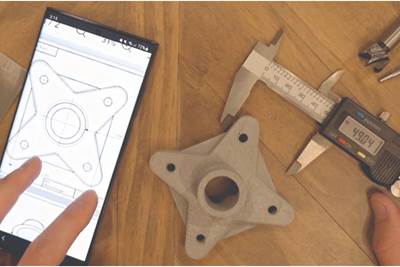

WatchFinally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

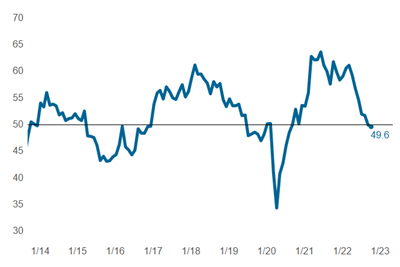

WatchMetalworking Activity Stays Flat in October

The GBI for Metalworking reflects stability of most of the six GBI components that had been losing ground months prior. Ordinarily underwhelming, flat is good when it means not contracting.

Read More5 Things CNC Operators Must Know About Sizing Adjustments

For CNC operators, sizing adjustment is an essential skill. Keep these points in mind when training new CNC users.

Read MoreMachining Questions? Ask the Expert

Meet John Miller, CNC expert and MMS’ newest columnist. In his new column, Miller’s Edge, he’ll answer reader questions about machining. Submit your questions today!

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreIntegrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Watch