MMS Blog

A Unique Additive/Subtractive Process for Injection Mold Components

This hybrid machining approach takes advantage of the benefits of deposition 3D printing while using CNC machining to overcome its limitations.

Read MoreHow Transparency Can Help Machine Shops Become More Efficient

Here are three areas that a machine shop owner can use to both share information and gather new information that would help them become more efficient and effective.

Read MoreBuilding Capacity Through Automation

Stecker Machine, a production shop that specialized in runs of a couple hundred parts, needed to develop highly automated cells to produce tens of thousands of complex parts from castings every year.

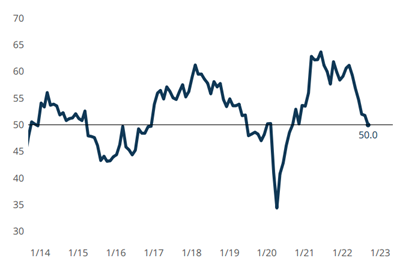

Read MoreMetalworking Activity Flattens in September

It has been nearly two years since the Gardner Business Index for Metalworking was 50.

Read MoreProcess Modernization is Scary but Necessary

When done correctly, process modernization can help secure a shop’s future in the industry and open new opportunities.

Read MoreWhen a Lathe With Live Tooling Rivals a Multitasking Machine

This shop is working its way up to a full-fledged B-axis multitasking machine. Meanwhile, turning centers with a Y-axis and live tooling are doing just fine.

Read MoreOEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

Read More3 Examples of Machines that Combine Manufacturing Methods

Certain “hybrid” machines combine some form of additive manufacturing with CNC subtractive manufacturing. Columnist Mike Lynch, President of CNC Concepts Inc., explores three types of these machines here.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

WatchDetermining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Read MoreWill the “Great Resignation” Become an Opportunity for Manufacturers? Get Ready for the Returning 3 Million

The Great Resignation will become a Great Reapplication when employees currently able to stay out of the workforce return to it looking for something better. Machining employers that are already evaluating candidates for fit, without demanding specific skills coming in, might be positioned well to draw upon this wave.

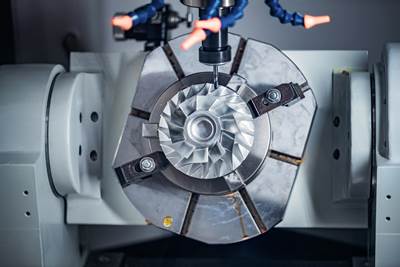

Read MoreWhy Go Five-Axis: Machine Types and Benefits

Even as the benefits of five-axis machining stack up year by year, the barrier for entry crumbles.

Read More