-

SPONSORED

-

-

-

-

-

MMS Blog

Global Metalworking Factory Investment Grows

The World Machine Tool Output & Consumption Survey

Read MoreAccessing Hidden Capacity in Medical Device Manufacturing

(MMS Online Exclusive) Data collection is an essential step in process improvement, allowing engineers to determine root causes and to ensure processes remained fixed permanently. The CNC machine tool is capable of capturing and communicating the status of operations and can be incorporated into a comprehensive automated data collection and analysis infrastructure that allows assigned resources to focus on implementing the best process improvements.

Read MoreEngineering The Toolholder Assembly Process

This assembly and mounting device for V-flange toolholders is designed to make it easier and safer to put toolholders, collets and cutting tools together. The device allows the toolholder to be clamped securely and rotated so that both ends of the assembly are accessible to the user in a comfortable position.

Read MoreGetting A Visual On Machine Maintenance

A software package allows real-time process monitoring of machine tools in operation. Its graphical interface speeds fault identification and machine servicing.

Read MoreThe Laser’s Role In Micromachining Metals

A new laser technology combines the high machining accuracy and throughput required for precision, industrial micromachining work.

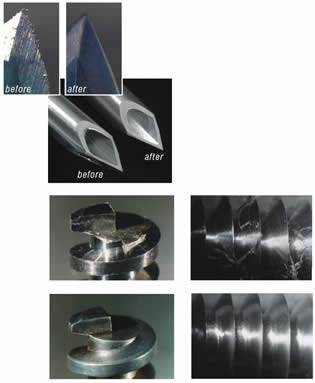

Read MoreSingle System Offers Multiple Finishing Processes For Small Parts

An electrochemical finishing technology geared toward small workpieces cleans, deburrs, passivates, polishes and stress relieves workpieces all at once.

Read MoreMolds In Miniature

A shop that makes tooling for metal injection molding (MIM) relies on a machining center designed specifically for micro-scale work.

Read MoreMachining And Racing

A visit to an automotive racing trade show revealed how some machining technologies are being applied to the production of hard core racing components.

Read MoreDecoding (Not Interpreting) GD&T

A suite of online applications aims to help all of the personnel involved with a part to read and apply GD&T information accurately.

Read MoreInspection With X-Ray Vision

Could detecting and quantifying the internal flaws of complex parts be as easy as operating a microwave oven? Kevin Legacy, manager of computed tomography (CT) and engineering at Carl Zeiss IMT Corporation, thinks so. He compares the manufacturer's Actis line of industrial CT systems to the one-button operation of the kitchen appliance.

Read MoreCompliant Machining Of Composite Wings

Bell Helicopter created a systematic, scripted process to machine composite wing skins and structural components for the V-22 Osprey vertical takeoff aircraft. Custom software ensures there is no deviation from the script.

Read MoreRelieving Bottlenecks At The Measurement Station

Throughput is as much an issue in measurement as it is in machining. Likewise, multipart setups can improve measurement throughput in much the same way they contribute to machining throughput. A special part fixture used in conjunction with an automated contour and surface-roughness measuring system allows four workpieces to be checked one after the other, with no operator intervention.

Read More