MMS Blog

Effective Plastic Machining Requires Effective Chip Control

Clean, burr-free cutting is fundamental to competitiveness for a shop that specializes in micro-machining complex geometry from some of the softest materials in the industry.

Read MoreGetting Started with Machine Monitoring

This shop’s successful entry into machine monitoring reveals important points about what to do and what to expect.

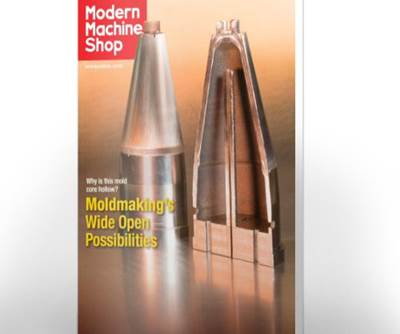

Read MoreMoldmaker Experiments with Hollow Mold Inserts as Alternative to Conformal Cooling

A plastics manufacturer with in-house moldmaking explores a different option for applying additive manufacturing to making mold tooling.

Read MoreBallnose Alternative Shines in Five-Axis Finishing

Large cutting edge radii facilitate higher-stepover passes that improve surface finish and reduce cycle time.

WatchSizing Up Rotary Table Advantages

Smaller may be better when it comes to rotary tables that enable a three-axis VMC to do five-axis machining.

Read MoreAdditive Manufacturing Makes Subtractive Cutting Tools

Mapal reaps the benefits of additive and subtractive manufacturing with its QTD drills.

Read MoreWorkholding Cuts Setup Time for Cylindrical Gears

A new generation of modular, quick-change workholding systems requiring fewer tools, less time and minimal operator experience has arrived.

Read MoreClosed-Loop Gear Production

A familiar concept is now gaining serious traction, enabling manufacturers to develop closed-loop cells that automatically match the finished product to design concept goals.

Read MoreDivisions Achieve Synergy Making Gears, Repairing Gearboxes

In addition to offering gearbox maintenance and repair services, this company is an OEM of new gears, harnessing the synergy between the two somewhat disparate divisions to the benefit of the overall enterprise.

Read MoreGet out the Vote for Manufacturing Education

A group of local manufacturers is pairing with teams from various high schools on a video competition that aims to educate students, teachers and parents about industry career opportunities. Today is the last day to vote!

WatchFreedom in Electron Beam Additive Manufacturing

The wire-fed EBAM process offers flexibility in part geometry and size—as well as material properties.

Read MoreWaterjet, Laser, or EDM... or Another Option?

The pros and cons of each process have been covered before, but at least one supplier’s technology bucks the trend.

Read More