MMS Blog

3 Things to Consider About Custom Gage Building

Custom-built gaging solutions take into account when, why and how measurement must be done to come up with the right system for the job.

Read MoreGrinding Equipment for Production, Flexibility, Automation

This month’s curation of products focuses on grinding machines and related equipment.

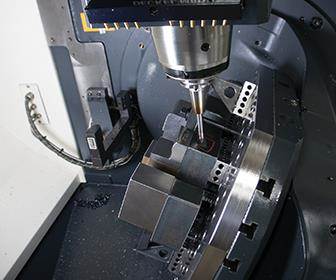

Read MoreFive-Axis Demands a Talented Supporting Cast

This mold manufacturer’s choice of workholding, programming and cutting tool technology helped maximize the time available to navigate the challenges of getting used to its first-ever five-axis machining center.

Read MoreCollet System Avoids Cutter Pull-Out in High-Feed Applications

Pioneer has developed a cost-effective collet system for high-feed applications in which cutters pull out from their holders.

Read MoreA Consultant's Tips for Growing Your Machine Shop

An outside salesperson is only one element of a coherent business development strategy, says David Bassler of Bassler Sales and Management Consulting. The entire team should embrace the following tips.

Read MoreInfographic: Careers in Welding

An illustration summarizes the work, compensation and opportunities in this field. Those opportunities sometimes involve travel and increasingly involve automation.

Read MoreConnecting Forklifts to the Industrial Internet of Things

ITAMCO, a manufacturer of precision-machined components and high-precision gears, has linked its forklifts to its network-based communication system. This connection to the Industrial Internet of Things (IIOT) significantly reduces the time it takes to get material ready for the next operation.

Read MoreWhat’s “Cavaforming?”

Armed with a 40-foot-long, 40-ton cold-forming machine that’s long been out of production, this mold manufacturer can produce tubular insert IDs with ±0.0002-inch tolerances and a 4-micron surface finish without EDM or polishing.

Read MoreTaking It Slow Pays Off for Learning Five-Axis Machining

A deliberately incremental approach helped this shop flatten a significant learning curve for collaborating on the postprocessor, easing setups and using cutting tools effectively.

Read MoreControl Capabilities Often Go Unused

The value of some control capabilities don’t become apparent until they are seen in use. Heidenhain supports its CNC users with a new Chicago-area training facility.

Read More“Smart” Generator Technology Makes EDM Operation Intuitive

GF Machining Solutions offers four generator features that enable users to input desired burning results into the CNC, and let the system do the rest.

Read More