Divisions Achieve Synergy Making Gears, Repairing Gearboxes

In addition to offering gearbox maintenance and repair services, this company is an OEM of new gears, harnessing the synergy between the two somewhat disparate divisions to the benefit of the overall enterprise.

Share

In business, when a department becomes too insular, rarely communicating with colleagues in other areas from whose insights they could benefit, it’s known as creating a silo. This can happen in a gear manufacturing shop when different divisions become so focused on their individual goals that they neglect to share observations and expertise, or fail to create a channel of communication, that would be helpful to the business as a whole. In most instances, each department would benefit from eliminating the walls that separate them.

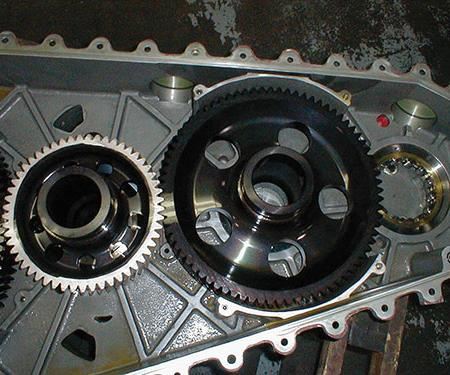

Long known for both designing and manufacturing new gears, as well as its gearbox repair service, Cincinnati Gearing Systems (CGS) is a stronger company because of the close relationship between these two different spheres of activity. Part of the OEM division’s success strategy is to remain at the leading edge of new developments in gear manufacturing, whether that involves new materials and designs for producing lighter, stronger gear sets, or the latest machining technologies for producing better gears more quickly. The service division works on maintaining and repairing older gearboxes of all makes, used in a variety of applications and working environments—all day, every day. Machine operators are cross-trained so that they can function in either setting, which not only creates flexibility in terms of human resources, but also leads to cross-pollination of a sort, with employees having the opportunity to work on both old and new gear sets, applying new technologies and materials to the gears they build and the gearboxes they repair.

By sharing the knowledge gained in each area with the other, the company is able to streamline its internal operations while providing customers with a depth of institutional knowledge that is constantly evolving and expanding.

Departmental DNA

Established in 1907, CGS is housed in three separate facilities in the Ohio city for which it is named. In addition to manufacturing precision component gearing and enclosed drives for marine, industrial and military applications, its gearbox repair service maintains both units that it designed and manufactured—sometimes decades ago—as well as gearboxes of other brands. Its original gearing is found in drives for compressors, expanders, pumps and marine propulsion systems. The shop’s capabilities include shaft grinding, turning, milling and cutting and grinding gears. Additional services include on-site heat treating as well as full load/no load testing on specially designed stands.

Although the OEM gearing division and the gearbox repair service are found in two different facilities, they are only a few miles apart, and interaction between the two groups is constant. While technical expertise is required in both areas, of course, an examination of how these two divisions operate individually reveals an entirely different approach to servicing their customers—almost two separate business philosophies, each tailored to the situation at hand.

“When you work with a customer on a new gear set, you generally have time to discuss different materials, designs, machining approaches and heat-treat methods to deliver the results they need at some future date. It’s a more methodical approach,” says Rob Rye, president of the company. “But when somebody’s gearbox has failed, they’ve got an emergency on their hands. They need us to get it back up and running quickly, because they can’t afford the downtime.”

To make a medical analogy, it’s the difference between a regularly scheduled visit to the doctor’s office and a mad rush to the emergency room after an injury. Each requires a somewhat different approach toward treating the patient.

Providing Options

When a new or established customer calls the gear repair service, the first thing that CGS must determine is the extent to which that customer wants its gearbox repaired. This can range from a quick fix to get it back online as soon as possible to a full rebuild, perhaps with new gear sets and bearings, which will take more time but result in a quieter, smoother running drive unit with an increased service life.

“It’s completely up to the customer,” says John Terry, service manager. “We give them a range of options to choose from as well as the risks and benefits of each.”

The fastest, least expensive approach might involve repairing broken gear teeth to the point that they are functional, or repacking bearings that should really be replaced, making clear this is a temporary patch meant to get the customer back in production, with the likelihood of a more severe—and expensive—failure looming on the horizon. CGS creates a detailed report listing all possible solutions, including the preferred method of repair necessary to return the gearbox to premium working condition. The optimal approach could involve replacing loose gears in damaged gear sets or the entire set, along with splines, shafts and bearings.

Conventional wisdom might indicate that the best way to avoid gearbox failure is to develop a preventive maintenance plan, either internally or by contracting with a service provider. Regularly scheduled vibration analyses, along with checking shaft alignment and bearing conditions, could help stave off disaster.

Should such a failure occur, however, CGS immediately begins working toward a solution, Mr. Terry says. He relates one example of a company that experienced a gearbox breakdown. This shop’s first concern, of course, was getting the gearbox repaired and back in action as soon as possible. Mr. Terry and his crew offered an alternative that involved getting the gearbox back to 50-percent functionality immediately, while at the same time designing and machining an entirely new gear set to be installed on completion. While this did not get the company back to full capacity immediately, it kept the shop working while it waited for the new gearing to arrive. In addition, the new gears CGS delivered were made of a stronger material for a higher power density, which allowed for a redesign to the gearbox so that it could carry a heavier load. Improved grinding techniques also provided the new gears with a better surface finish.

“Instead of being down for 12 weeks with a catastrophic failure, they only lost a couple of days,” says Rodger Kahrs, CGS sales and service representative. “And then we went to their site, installed the new gears, ran them at top speed, fully loaded, and checked the support equipment on either side of the gearbox, because that’s often where the problem actually occurs. Sometimes people even try to force the alignment when they’re putting in a gearbox in order to get a bolt in a hole, and that will tear your gear

set apart.”

The Leading Edge

At the same time that CGS’ repair service is taking apart older gearboxes, many of which CGS originally made—an excellent opportunity to review performance and rethink dated designs—the OEM division is constantly striving to learn about the latest cutting tools, software, materials and machining processes for manufacturing new gears that will allow the company to remain competitive in a crowded field. This has led to major capital investments, including a Giddings & Lewis vertical turning center, a Johnford horizontal mill, an Amera-Seiki vertical turning lathe, Reishauer and Gleason high-speed forming grinders, and a Usach CNC outer-diameter grinder. According to Kenneth Kiehl, vice president of sales and engineering, with a nice balance of advanced new equipment and reliable “old iron” on hand, CGS is prepared to meet whatever tolerances a customer requires and to machine gears from 3/4 inch in diameter to 4 meters in diameter at American Gear Manufacturers Association quality levels up to Q15.

Mr. Kiehl goes on to describe advances made in machining processes the company utilizes that have led to faster, easier production of higher quality new gears as well as better reconditioned gears for the gearbox rebuild operation. When it comes to milling, for instance, new techniques enable gearbox cases to be machined in ways that allow for improved material removal in areas that couldn’t be reached before, resulting in lighter enclosures with more room for the gear sets. This even makes it possible to “re-ratio” the gear sets to carry heavier loads within the same outer dimensions of the original gearbox design. And these gears—whether they are new or reground—benefit from improvements that have been made in both grinding machines and the abrasives adhered to the wheel, resulting in gears that run more quietly, smoothly and for longer than in days past. It’s also possible to bring secondary or tertiary operations such as deburring and chamfering “into the machine,” eliminating an extra setup in many cases.

Cutting tools are in a constant state of evolution, as any machine operator knows, but Mr. Kiehl says CGS has a unique way of getting the exact tooling it requires, thanks to an experienced on-site cutting tool engineer. “When he needs a tool for a particular machining process, he’ll order the closest thing he can find from our vendor and then make slight modifications that ‘tailor’ the tool to the machine and process for which it is intended,” he says. Fixturing is also developed in house for each individual job and workpiece.

Another manufacturing need that is constantly being improved is available CAD/CAM software that automates and streamlines many processes that once required manual adjustments. CGS uses SolidEdge software for its CAD design and SmartCAM CNC for machining. The 3D model step file, developed using SolidEdge, is used to check the machining of the modeled part before cutting chips. Often utilized on the rebuild side is the “Unknown Gear Measurement Program,” which quickly determines the geometry and dimensions of unknown gears.

One final area the gear service division addresses is making improvements to support components, such as bearings and seals, with the goal that a rebuilt gearbox is returned to the customer in better running condition than when it was initially manufactured. While bearings can sometimes be reconditioned if they are out of round, new products such as CARB toroidal roller bearings from SKF combine the self-aligning capability of spherical roller bearings with the axial displacement ability of cylindrical roller bearings. The bearing manufacturer says these bearings deliver the compact cross-section and high-load carrying capacity normally associated with needle roller bearings. Although seals are now made of more durable materials than before, they can still wear grooves in pinions and shafts over time. In some cases, CGS solves this problem by attaching a collar made of a material harder than the shaft in order to protect it from contact with the seal.

Seeking Synergy

Although the communication between the two CGS divisions is constant and ongoing, it’s constructive to review the “back and forth” nature of the knowledge they exchange. Here are benefits Mr. Kiehl cites:

Value transfer from OEM to repair division:

-

To remain competitive, the OEM side must be aware of new materials and gear designs,allowing the service side to return a better product to its customers.

-

The new machines purchased for the OEM side hold higher tolerances, improving the quality of the gears used in gearbox repair.

-

Investing in leading-edge machine tools allows the service side to bid on work it couldn’t have otherwise.

-

It is good marketing for the gearbox repair service to also be an OEM as proof of its knowledge and experience.

Value transfer from repair to OEM division:

-

The examination of gearboxes in active use for long periods of time, in various applications, helps the OEM side improve new gear set designs.

-

Maintaining gearboxes that were originally made by the company provides insights into how its products, including components such as seals and bearings, hold up.

-

Repairing gearboxes of all makes and types on a daily basis provides the company’s gear repair specialists with a wealth of experience to share with OEM operations.

-

Developing a relationship with a customer through a gearbox repair often leads to opportunities to bid on new gear set designs.

Mr. Kiehl likens the gearbox repair service to automotive maintenance. “We design, manufacture and assemble the entire box, including the shafts, gears, bearings, seals and lubrication systems, so returning your gearbox to the OEM is like taking your car to the dealer instead of an independent mechanic.”

Inner Resources

Just as a successful gear manufacturer is constantly seeking outside resources to improve operations—training, trade shows, OEM open houses—it also draws from internal resources, such as expertise that can be translated across different platforms within the company. Learning to make new, better gears allows the repair side to thrive, while constantly reviewing older gearboxes identifies design weaknesses that can be addressed with newer and better designs, improved materials, and agile machining processes that lead to better drive systems and components.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)