MMS Blog

It's Time to Educate the Next Generation–Manufacturing Competitions Receive Support from Companies at SkillsUSA

The depiction of manufacturing jobs as dirty and undesirable may soon be a thing of the past. How are manufacturing companies showing their interest in getting more students into the field?

Read MoreGardner Business Index: Metalworking June 2016 – 44.4

Decelerating contraction in capital spending is a positive sign for equipment consumption.

Read MoreCapturing Captive Knowledge

Tell me if you’ve established a means for culling your experienced machinists’ shopfloor knowledge before they retire.

Read MoreCrossing the Skills Gap One Student at a Time

Every year, thousands of high school and college students who are enrolled in public career and technical programs make their way to the SkillsUSA national-level championships to compete for scholarships and awards. These students are the best in their states and are part of a growing movement to ensure that America has a skilled workforce.

Read MoreMake Large Prototypes on a Small 3D Printer

To prove out the designs of brackets that are much larger than its 3D printer, this manufacturer prints the bracket models in pieces and assembles them into prototypes.

Read MoreAutomation Evangelists Cast Wide Net

This recent event was hosted by a network of suppliers in a single location touting a single message: Automation isn’t necessarily time-consuming and expensive, even for smaller shops.

Read More3D Laser Scanner Automatically Captures Millions of Data Points

ShapeGrabber, a division of Quality Vision International, presents its line of 3D laser scanning systems featuring the Ai310 scanner.

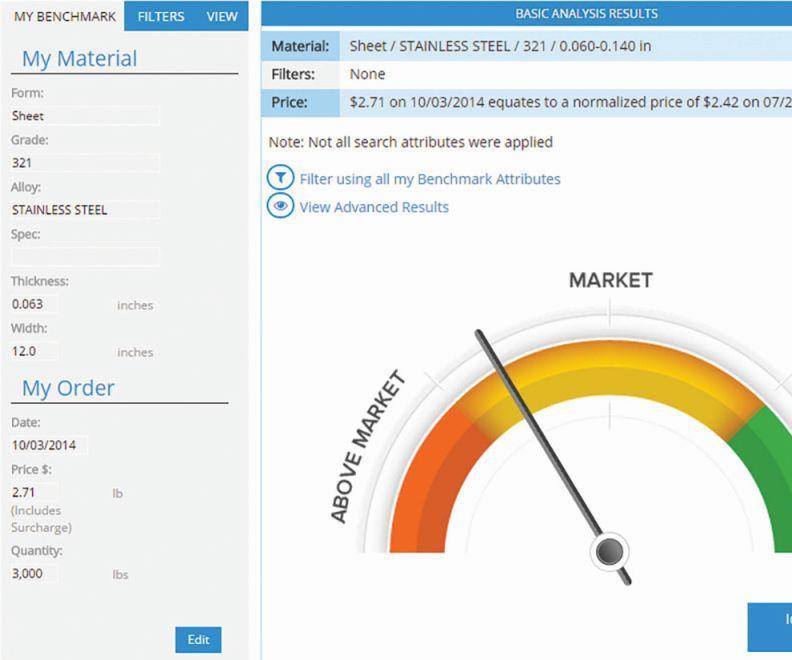

Read MoreOnline Benchmarking Site Helps Shops Price Metals More Effectively

Price Dynamics is designed to overcome pricing uncertainties when it comes to buying raw materials.

Read MoreTool-Changing Electrospindle Makes Every Second Count

In addition to offering all the advantages manufacturers have come to expect from an electrospindle, this design incorporates a multistation carrier to reduce tool-change time on custom machinery and robots.

Read MoreTake Your Son to Work Day (Sort of)

A recent visit to a local machine shop enabled young folks, including my son, to get a better appreciation of what modern manufacturing is all about.

Read MoreLights Off, Profit On

Various tooling considerations contribute to profitable lights-out machining.

Read MoreMazak SmartBox at Cisco Live

Later this month, Mazak Corp. will present the next phases of its Mazak SmartBox at Cisco System Inc.'s Cisco Live event in Las Vegas. In addition, notable organizational changes in the top management positions at Mazak will be apparent.

Read More