Mazak SmartBox at Cisco Live

Later this month, Mazak Corp. will present the next phases of its Mazak SmartBox at Cisco System Inc.'s Cisco Live event in Las Vegas. In addition, notable organizational changes in the top management positions at Mazak will be apparent.

Share

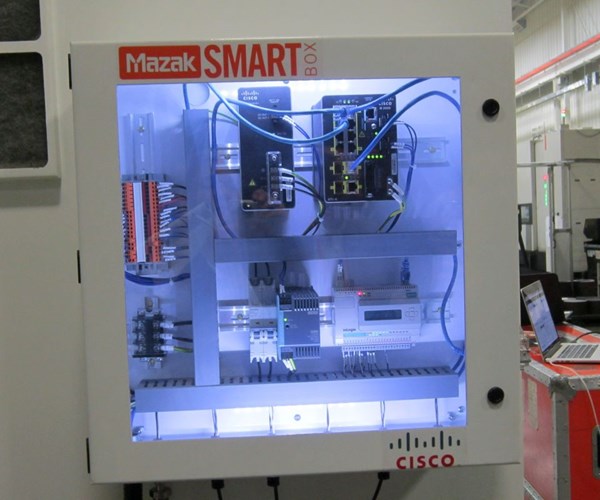

The Mazak SmartBox with cloud connectivity encompasses integrated services such as secure file transfer, remote access and machine history.

Later this month, Mazak Corp. will present the next phases of its Mazak SmartBox at Cisco System Inc.'s Cisco Live event in Las Vegas. This announcement is significant for several reasons:

- Mazak is continuing to show leadership in the transition to data-driven manufacturing throughout the industry.

- Cisco Systems is taking serious interest in the networking, security and connectivity needs of the Industrial Internet of Things (IIoT)—the essential infrastructure that enables data-driven manufacturing.

- In addition, notable organizational changes in the top management positions at Mazak will be apparent.

In announcing its participation at Cisco Live, Mazak states that, in its next phases, the Mazak SmartBox IIoT platform (developed in collaboration with Cisco) will offer Mazak iSmart Cloud connectivity, machine learning and predictive maintenance capabilities, in addition to process analytics. The Mazak SmartBox enables manufacturers to access and use real-time manufacturing data to improve productivity and react quickly to customer needs. Likewise, iSmart Cloud connectivity helps shops identify machine issues before they escalate into machine downtime.

Cisco Live, described as the one of the industry’s largest such events, will focus on process analytics as well as ideas and technologies to optimize factory floor performance and production. More than 1,000 technical sessions will take place and cover various topics involving the IIoT, analytics and manufacturing. This event signifies the merger of corporate and factory-floor information technology.

Mazak will be a special guest at the Cisco event. Mazak’s Daniel Janka will participate in panel discussions and present on Mazak’s use of the SmartBox technology within its own iSmart Factory in Florence, Kentucky. This will mark one of Mr. Janka’s first public appearances as company president, replacing Brian Papke, who has accepted a new position as chairman. As of July 1, Mr. Janka will assume the normal operating functions of Mazak’s North American operations, including the iSmart Factory and North American Headquarters in Kentucky, along with the company’s eight Technology Centers located throughout North America.

The company says it is positioning itself for continued growth and further advances in the manufacturing industry’s new digital frontier, as well as developing technology in multitasking, five-axis machining and additive manufacturing. The company says Mr. Papke personally selected Mr. Janka, who joined Mazak in early 2016, because his experience in the machine tool industry and his extensive involvement with machine tool utilization software and five-axis technology at past positions meshes well with Mazak’s iSmart Factory and the company’s commitment to MTConnect.

Mr. Papke has been with Mazak since 1987, and company president since 1989. Under his leadership, the Kentucky plant grew from one building to its current five-building, 800,000-square-foot campus where the company now designs and builds advanced manufacturing systems, including five-axis and multitasking machines. Mr. Papke promoted the iSmart Factory Concept and the Mazak SmartBox to facilitate further integration of digital solutions in manufacturing.

Related Content

-

Leveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

-

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.