Tool-Changing Electrospindle Makes Every Second Count

In addition to offering all the advantages manufacturers have come to expect from an electrospindle, this design incorporates a multistation carrier to reduce tool-change time on custom machinery and robots.

Share

The slightest delay can feel like an eternity in applications that call for dedicated equipment, whether a custom-built machine tool or a programmable robot that frees other resources from light machining tasks. With a new electrospindle from ITI Tooling, such equipment can be configured to shave a few additional seconds of cycle time from any job that requires frequent tool changes.

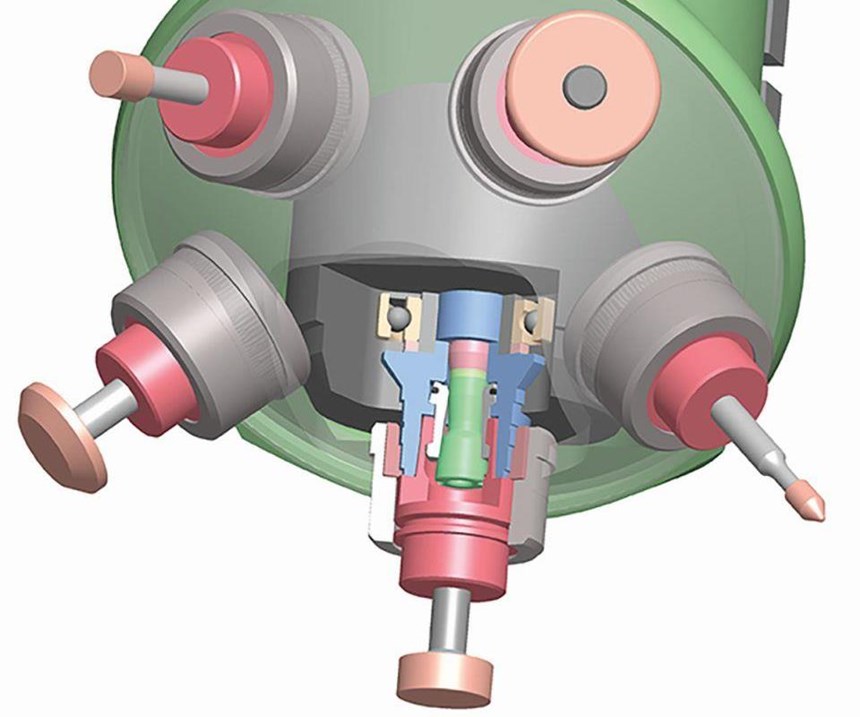

Featuring an integrated tool carrier, the ATC series electrospindle enables swapping to a fresh milling cutter, turning cutter, drill, tap or grinding wheel in approximately 1.5 seconds. That’s markedly faster than most electrospindles paired with a separate tool-changing mechanism, says company President Mike Bickham. The ATC spindles also offer advantages over many standard tool turret designs.

Aside from the tool carrier, the unit’s design is quite similar to that of many other electrospindles, he says. The defining characteristic of this technology is an electric motor that’s integral to the unit, thus eliminating the need for belt drives or other mechanical means of transmitting power. This construction enables suppliers to offer a wide variety of motor options for different balances of speed and torque. The ATC series, for instance, offers speeds ranging from 24,000 to 80,000 rpm and torque ranging from 0.3 to 60 Nm (the faster the speed, the lower the torque). This wide range of capabilities makes electrospindles a popular choice for installation on robot arms as well as specialized rotary transfer machines and other machine tools that are custom-built for specific applications.

Although many electrospindles are available with automatic tool-changing capability, most employ an external arm to transfer cutters to the spindle, whether from a stand-alone tool-storage station or a magazine installed on a custom machine tool. In either case, these tool changes might take 5 seconds or longer, Mr. Bickham says. A change might take even longer in the case of an electrospindle mounted on a robotic arm, a common setup for specialty applications such as trimming flash from die-cast automotive components. After all, the robot might have to maneuver around fixtures, workpieces, other tools, the tool-storage station itself or any other potential interference points along the way, he says.

The ATC series suffers from no such drawbacks. What’s more, the line demonstrates that the addition of a multi-station tool carrier to the business end of an electrospindle doesn’t have to affect the fundamentals of its operation, Mr. Bickham says. After the drawbar releases the first tool from the HSK interface, the carrier moves forward approximately 0.25 inch to clear the holder from the interface before rotating to line up the next tool. The new tool installs directly into the spindle shaft, just as it would on a model without a multi-station carrier.

Mr. Bickham places particular emphasis on the point that the carrier is just that—a carrier. That is, no tool but the one installed in the HSK interface is ever under power. That’s a contrast to some tool turret designs that mount tools in long, extended-cartridge spindles. Such construction makes these units more prone to vibration than an electrospindle, particularly given the fact that they tend to incorporate conventional rather than high-precision bearings, he explains. The fact that electrospindles are also more compact—that tools operate closer to the spindle body—also helps reduce vibration and heat. The pressurized, sealed spindle body is also internally cooled, a feature not shared with most standard turrets.

Although the angle of the tool carrier helps ensure stored tools don’t interfere with access to machined features, manufacturers should carefully consider the orientation at which the spindle is mounted, as well as the number of tool stations. Users are typically discouraged from opting for any more than eight stations, although more are available for the right application, Mr. Bickham says. With a bit of care, however, an ATC series spindle can boost productivity on any application that requires frequent tool changes, whether the job calls for multiple, redundant tools or a series of different operations.

Related Content

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)