It's Time to Educate the Next Generation–Manufacturing Competitions Receive Support from Companies at SkillsUSA

The depiction of manufacturing jobs as dirty and undesirable may soon be a thing of the past. How are manufacturing companies showing their interest in getting more students into the field?

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreWithout the chance to see for themselves what a job in the manufacturing sector could hold, many young people like myself (I’m 16 and completing an internship at Gardner Business Media this summer) are said to be turning their heads away from the industry entirely. According to the 2015 Skills Gap survey conducted by The Manufacturing Institute and Deloitte, “only 37 percent of respondents in the 2015 study indicated they would encourage their children to pursue a manufacturing career,” even though most respondents agreed that manufacturing is essential to our national economy.

The prevailing perception of dirty, undesirable manufacturing jobs has harmed the desire of students to pursue an education in these sectors. Recent activities by manufacturing companies at this year’s SkillsUSA competition, however, indicate that by promoting their industry they can have a positive influence on the career decisions of today’s youth.

In other words, there is hope for the manufacturing industry, and an improved perception of the skilled engineering workforce may soon engage a new generation of inspired young college graduates interested in being a part of modernized machining.

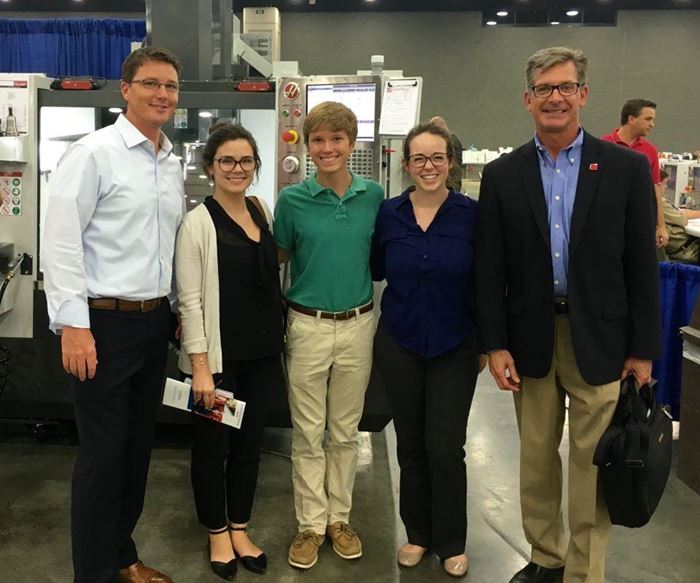

Attendees to this year’s SkillsUSA competition in Louisiville, Kentucky, may have noticed this change in action, especially in the manufacturing competitions. As a trade, manufacturing, both additive and subtractive, dominated the four-day long event in terms of monetary support and vendor representation.

I had the opportunity to attend the championship competitions at the skills conference, and I noticed that companies like Haas and Stratasys wanted the students to have the best equipment to demonstrate their skills in additive and subtractive manufacturing.

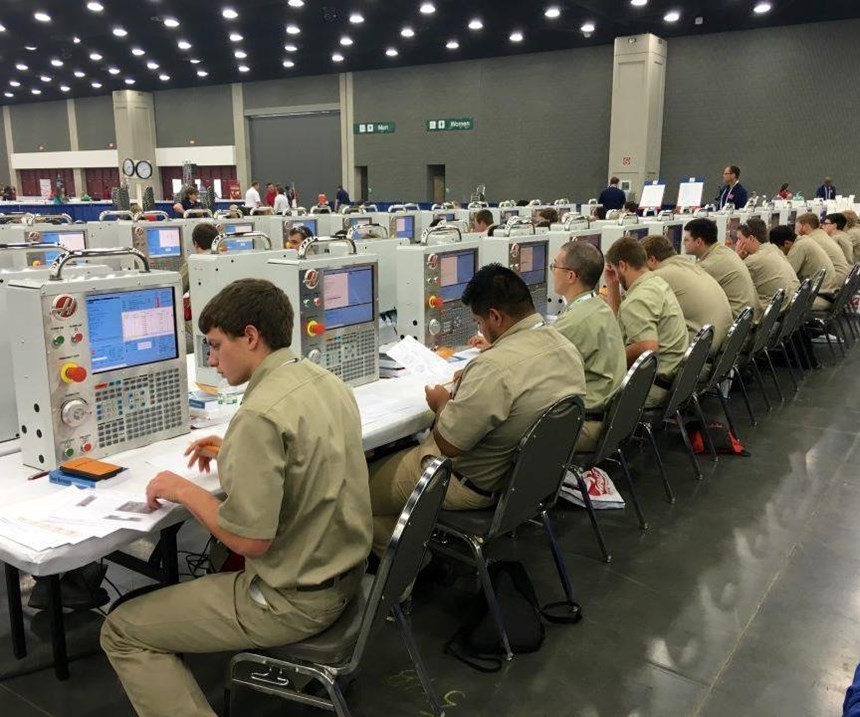

At SkillsUSA, the manufacturing and machining trades competed in skill-based competitions like metalworking, programming in G code, robotics, 3D printing, automation, CNC milling and CNC turning, to name a few. For instance, one automation competition consisted of programming a robotic arm to pick up and deposit blocks on a conveyer belt whereas one of the G-coding competitions consisted of using a CNC control to graphically create a usable code to mill a part. The majority of competitors were in high school or college, but I was surprised to hear that the youngest competitor was 13 and the oldest was 73.

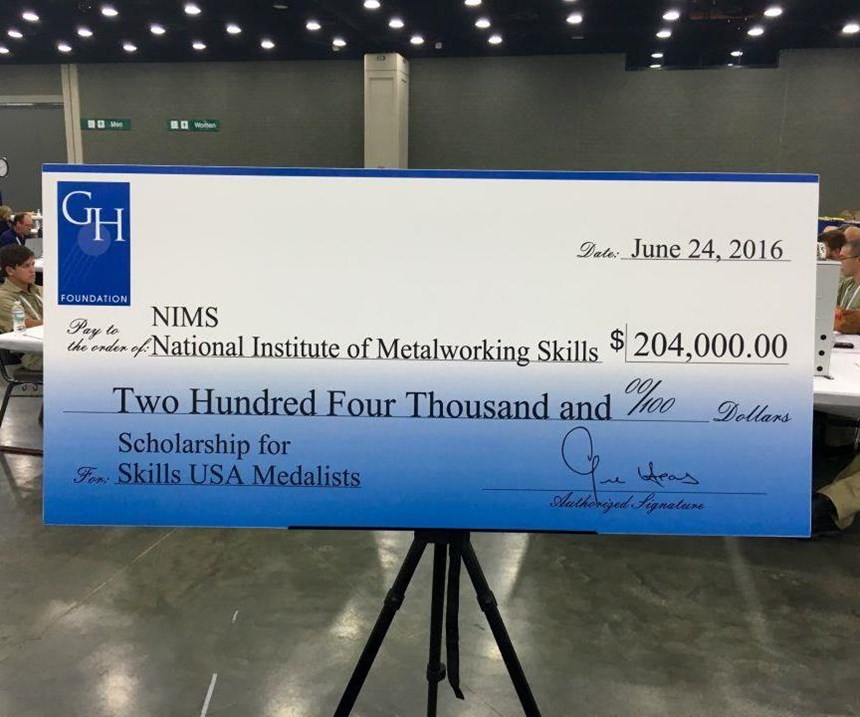

On top of donating equipment for these competitions, several manufacturing companies were incentivizing competitors in the trades they were involved by offering monetary scholarships to the winners of these skill areas. As a generous donation to the competitions as a whole, the National Institute of Metalworking Skills (NIMS) donated a prize of $204,000 to SkillsUSA medalists.

Manufacturing companies are realizing that the next generation of engineers and manufacturers can’t be ignored–students must be incentivized and empowered. At SkillsUSA, these companies showed that they understand the importance of stimulating a new generation.

Because of the support from manufacturing companies at SkillsUSA, students like me can see the promise of a manufacturing career.

Max Egan will be a junior at Turpin High School in Cincinnati, Ohio this fall, where he is involved in cross country, track, student council and choir. His favorite part about the internship has been the opportunity to explore the applications of manufacturing and engineering in the real world through field trips and research. When Max graduates and moves on to college, he hopes to use the skills he has learned over the summer to form the foundation for a major in mechanical or environmental engineering and delve deeper into the science of sustainability.

Related Content

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)