MMS Blog

Webinar: Quality Management Systems for Additive Manufacturing

A free webinar on June 14 will discuss how to modify quality management systems to suit additive manufacturing applications.

Read MoreInside Haimer’s Expanded North American Headquarters

The company’s shrink-fit, balancing and tooling technologies are on display in a new 25,000 square-foot facility.

Read MoreMachining Critical Crane Components

By investing in a new horizontal machining center with a two-axis head and a six-station pallet pool, this crane OEM is making critical components for telescopic booms in one setup and running lights-out.

Read MoreShop Favors Different Flavor of Five-Axis Technology

Campbell Engineering benefits from a new twist on the tombstone workholding concept, which enables one of its HMCs to perform 3+2 machining to reduce scrap while supporting the higher-volume needs of its medical customers.

Read MoreConstant-Chip-Load Machining Yields a Better Tool Path

With its in-house R&D program, this aerospace shop seeks to be a leader, not a follower, on the path to innovation in advanced manufacturing. Finding and embracing a better way to generate tool paths for highly efficient and economical metal removal is a prime example of the value of this program.

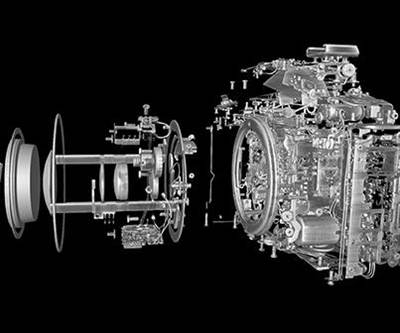

Read MoreAn Improved Method for Machining Blisks

A software designer and a tool maker collaborate on a system for machining blisks that focuses on the point of contact between the workpiece and the cutting tool.

Read MoreHow Steinway Machines Its Pianos

A custom-designed five-axis dual process CNC router allows a piano builder to machine a critical part more quickly, retaining the quality of tone for which it is known.

Read MoreCT Scanning Moves from Lab to Production Line

In addition to raw computing power, new microfocus source designs and intuitive software make this technology ready for the production line.

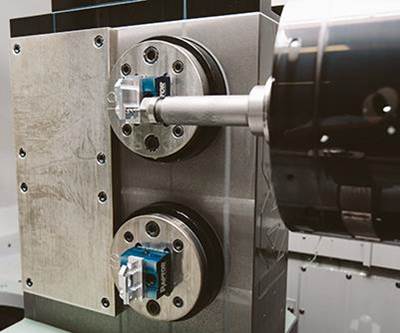

WatchOn-Machine Verification Keeps Process Chain Intact

Measuring on machining centers is no substitute for this mold manufacturer's CMM. Rather, the goal of on-machine probing is to minimize downtime at individual workstations and to maximize overall throughput.

Read MoreRedefining the Rustbelt

From Akron, Ohio, to Albany, New York, former manufacturing towns are charting a course toward a brighter future as a hub of innovative thinking leading to the production of smarter products, not just cheap ones.

Read MoreVirtual Training Helps High Schools Teach CNC Skills

Machine Training Solutions is paving the way to bring virtual CNC training and mentoring to high school honors students.

Read MoreIngenuity Meets Automation. Lunch Meets Learn.

Sponsored Content – IMTS 2016 Technology eNewsletter

Read More