Articles

Takeaways From TASC

Across a range of technical presentations aimed at small and mid-sized job shops, the first-ever Automated Shop Conference (TASC) offered insights into several automated technologies, implementation strategies, shopfloor training tips, and even the untapped power of automated coolant delivery.

Read MoreAutomation Plus Capabilities Beyond Machining Featured at Mazak Event

Friction stir welding is one example of a capability for emerging applications that changes the scope of the machine tool. Here are observations from Mazak’s Discover 2023 event.

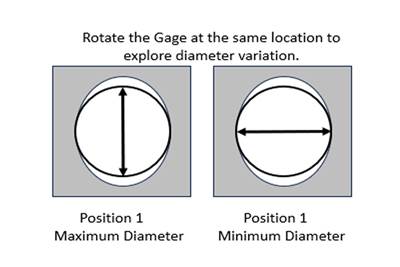

Read MoreTips for Anticipating Hole Conditions

When measuring an ID with an indicating plug gage, it is OK to slow down to learn more about the hole being measured and explore for extraneous conditions.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

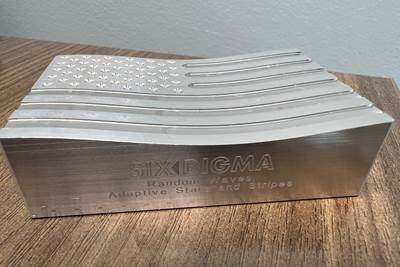

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

WatchMetalworking Activity is Nearing a Full Year of Contraction

Metalworking activity has contracted since October of 2022.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

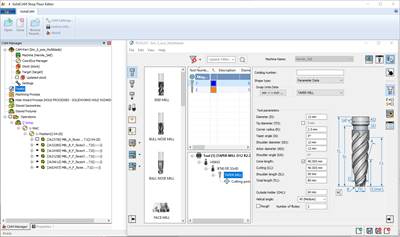

WatchBuilding A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

WatchSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreMarposs Celebrates its Past, Eyes Future Opportunities

During its open house in Auburn Hills, Michigan, Marposs presentations focused on future opportunities across growing industries such as EV and semiconductors.

Watch