Contour-Following Stylus Speeds Dot-Peen Marking

Capability to mark surfaces at widely varying heights and difficult-to-reach areas makes pneumatic systems more competitive by reducing the need for special fixtures and other accessories.

Share

This video from Technifor shows its dot-peen marking stylus in action.

The overall speed of a dot-peen (micro-percussion) marking application depends on far more than the number of characters a system can produce in a given amount of time. Jobs that require marking at widely varying heights or in difficult-to-reach areas often call for enough troubleshooting and labor during setup to eclipse savings provided by even the fastest equipment.

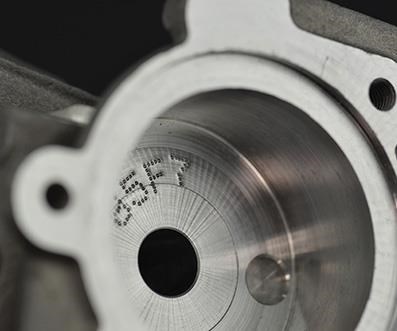

At least, that’s what Technifor, a division of Gravotech, has been hearing from customers reporting increased demand for product traceability throughout the industry, says Bon Carter, business manager for industrial manufacturing companies. In response, the company has unveiled a high-amplitude stylus, one that enables users to significantly expand the vertical work envelope of pneumatically driven equipment without adding accessories, adjusting settings, or raising or lowering the marking head. Aptly dubbed the 3D Stylus, this niche product automatically extends and retracts within a 16-mm vertical range as it follows the relief of the part surface. By comparison, the amplitude (vertical range) of the supplier’s other pneumatic systems tends to be limited to about 6 mm, Mr. Carter says.

Like their electromagnetic cousins, pneumatic dot-peen marking systems drive a pointed carbide pin, or stylus, into the part surface hundreds of times per second to create a series of indentations that form figures, shapes and patterns. However, electromagnetic systems offer capabilities that tend to make them more expensive and less common. With the 3D Stylus, pneumatic users can narrow the gap, Carter says. “With this product, we’ve advanced pneumatic systems in the technological arms race by enabling them to throw the stylus even farther than comparable electromagnetic systems,” he explains, noting that the amplitude of most electromagnetic systems range to about 12 mm.

The same design features facilitating a longer stroke help level the playing field in other areas as well, he says. Whether the stylus is mounted in a benchtop machine, a portable machine or a marking head integrated into a broader line, basic operation is the same as any other pneumatic model. That is, a valve on the machine admits shop air to a piston, which generates a consistent level of pressure to force the stylus into the workpiece. On the way down, a series of exhaust ports evacuate air, thereby freeing a built-in spring to recompress and bring the stylus back to home position. However, the newer design differs in terms of the weight and balance of the stylus, the size of the piston, and the design and configuration of the exhaust ports. The net effect of these features is a stylus that strokes less frequently (about 20 times per second, compared to 300 times for most pneumatic styli). By extension, it generates less noise and uses less air (roughly 29 psi, versus about 80 psi for standard models).

However, the slower rate of impact is even more important for its role in facilitating the 3D Stylus’ most defining feature: its high amplitude. After all, Mr. Carter explains, the farther a stylus travels, the more time it needs to return to home position before the feed continues. Granted, fewer impacts in a given time period translate to a slower overall marking process. However, he emphasizes that overall time savings far eclipse any losses in the right application: namely, the marking of multiple surfaces that vary more than a few millimeters in height.

Whatever the situation—stepped geometry, sloped or curved planes, distorted or uneven surfaces, recesses, protrusions—manufacturers’ marking options are typically limited in such scenarios, Mr. Carter says. Depending on the configuration of the marking system, some simply raise and lower the head manually as needed. Others invest in machines with programmable Z axes or mount the marking head on a Z-axis slide. However, the former takes time and requires attention from employees, while the latter requires additional motion and additional programming. Either would be far slower than a stylus capable of following any contour without requiring any extra input, Mr. Carter says. Similarly, the 3D Stylus provides a cost-effective alternative for jobs that would otherwise require special fixturing, such as tooling that holds multiple, different-sized parts at the same Z-axis level, or a rotary attachment for cylindrical components.

The 3D Stylus is available with three tip angles: 60 degrees, which the supplier recommends for deep marking and small data matrix codes; 90 degrees, which is said to be the most versatile option; and 120 degrees, which is recommended for raw or hard surfaces. Swapping one stylus for another, whether for a different 3D Stylus or a conventional one, takes only seconds, Mr. Carter says.

Related Content

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More