Shop's Own Training Program Paves a Pathway to Employee Success

This shop developed a Web- and video-based training program tailored to its own specific practices that enables new hires to progress in stages from trainee to senior process engineer after demonstrating a clear understanding of each new skill they’ve acquired.

Share

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

This is an example of a training video LeanWerks produced explaining how to properly fill out first- and final-article inspection reports for a given job. It is one of 130 custom training videos the company has produced to support its TExT apprenticeship program.

These days, you’re simply not going to get a steady flow (heck, not even a trickle) of experienced machinists or vocational school grads applying for a job at your shop. This has spurred many shop owners and managers to take matters into their own hands by developing some flavor of in-house training or apprenticeship program for prospects who have a nice mix of “soft skills,” as well as the openness to consider a career in machining.

These efforts vary in sophistication from simple shadowing of experienced shopfloor employees to more formal, structured programs. LeanWerks, led by company president and founder Reid Leland, decided to take the latter approach, establishing its Technical Excellence Training (TExT) program in 2010. Mr. Leland says in doing so, the company was able to take control of its own destiny in terms of filling its own pipeline with shopfloor talent.

The TExT apprenticeship program is different than other home-grown initiatives I’ve encountered, as is demonstrated by the following five goals the shop identified while developing it:

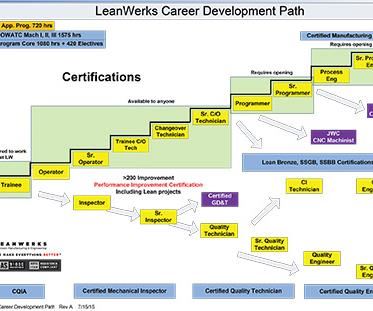

- Provide a clear pathway leading to a machining career. As shown in the chart on the facing page, new hires can decide how far they’d like to advance on a career path at LeanWerks, which offers 10 levels of professional qualifications ranging from trainee to senior process engineer (understanding that the top four levels require there to be a job opening). Certification in various quality control and continuous improvement concepts is offered, too.

- Break the common four-year journeyworker certification process into smaller segments. Employees receive certificates each time they complete a TExT course, unlike conventional programs in which the payoff of a certificate doesn’t come until after an entire four-year program is completed.

- Customize the courses based on the shop’s specific processes. A general shop training curriculum isn’t the best option for LeanWerks, because many of its repeating jobs involve specialized machining and manufacturing processes. The specific lessons within the custom courses it developed also serve to standardize processes, eliminating any person-to-person variation from the way the tasks are supposed to be performed.

- Make use of video. Many lessons include instructional video taken of actual LeanWerks shopfloor processes and practices to clearly outline the steps required to complete a given task safely and effectively. To date, the shop has produced more than 130 such videos for its TExT program.

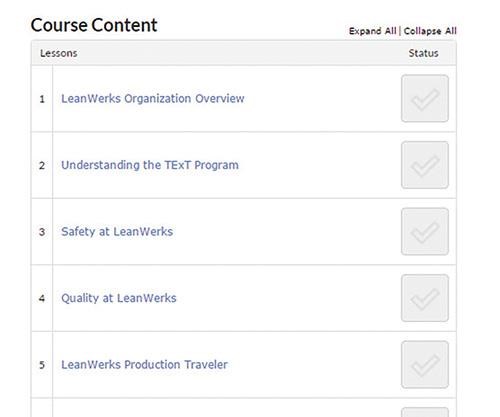

- Simplify employee access and manager administration. An intuitive, Web-based platform makes it easy for employees to access lessons, as well as for the shop to manage the program, having the capability to prevent employees from proceeding to subsequent lessons until they have demonstrated a firm understanding of the material presented in the one they’re currently studying. As it turns out, the cost of the software used to administer the program is relatively low, too. The program is based on a basic website-hosting platform modified with an inexpensive learning management system plug-in.

Mr. Leland says the program got a shot in the arm one year after LeanWerks began implementing it when the shop hired Paul Harbath to be its director of quality and continuous improvement. A 27-year manufacturing veteran with 14 years of lean-manufacturing consulting experience, Mr. Harbath has been key to helping develop TExT lessons, courses and instructional videos, and now serves as the program’s administrator. During a recent visit, he and Mr. Leland explained what spurred the shop to develop its custom TExT training program, how it functions and what lies ahead in terms of its expected certification through the U.S. Department of Labor (DOL).

Program Path

Mr. Leland started LeanWerks in 2003. His wife, Suzanna, is CEO and CFO. Although a large portion of the Ogden, Utah, company’s business had been devoted to the oil and gas industries, the contract shop has diversified itself by pursuing work for fluid power, defense, high-speed manufacturing and aerospace applications. In fact, Mr. Harbath led the shop’s efforts last year to become registered to the AS9100C aerospace standard without any findings in the initial audit. The shop is also registered to ISO 9001:2008 and Directorate of Defense Trade Controls (DDTC), which is a prerequisite for International Traffic in Arms Regulations (ITAR) compliance.

As its name suggests, LeanWerks has made strides to establish a lean-manufacturing mindset, implementing practices such as 5S workplace organization, value stream mapping, kaizen events and cellular manufacturing. The goal is to wring as much waste as possible out of its production processes while fostering a culture of continuous improvement. The TExT program complements this approach in that it offers a streamlined means to train new employees based on the shop’s own lean processes and procedures.

One of the first steps in creating the TExT program was finalizing the 10-level career path and identifying course segments. Each new hire begins with a shop fundamentals course that spans a 90-day introductory period and explains what LeanWerks and the TExT program are all about, in addition to introducing them to very basic shop concepts. It’s at this stage that they sign a confidentiality agreement, too. In fact, that’s the first “lesson” in that first course.

The introductory period benefits both the employee and the employer by enabling new hires to determine if a career in machining is something they truly want to pursue while affording the shop time to determine if the prospects are actually cut out for that type of work.

Those who pass this initial course receive a certificate of completion and are permitted to begin the career development portion of the program, which starts with the machine operator course. As shown in the screen capture on the facing page, this course is divided into a 10 lessons, and each of these covers a variety of topics. For example, topics inside the “Basics of Tooling” lesson address insert removal and replacement, mill and lathe offsets, touching-off tools, proper vending machine use, etc.

Mr. Harbath says it typically takes a person six months to complete the machine operator course. The next course made available to him or her is senior operator, which takes nine months to one year to complete, followed by trainee change-over technician (one year), change-over technician (1.5 years) and senior change-over technician (1.5 years). Although the shop allows anyone to proceed from trainee to senior change-over technician, a job opening is required to become a programmer, senior programmer, process engineer or senior process engineer.

The TExT program also includes courses for those who would like to become certified mechanical inspectors, quality technicians or quality engineers. In fact, all employees who enter the machine operator course must also take a CMM operator course, because they might at some point be required to inspect their own parts on the shop’s CMM. Similarly, courses related to continuous improvement are offered, such as Six Sigma Green Belt, Black Belt and so on.

Program Administration

Mr. Harbath says that early on, TExT program administration was cumbersome, largely because it required manual management of complex spreadsheets for each employee. After some investigating, he eventually identified a more effective solution in Web-based software that was intuitive, easily customizable and very inexpensive.

LeanWerks chose WordPress, a popular website- and blog-hosting platform, so that it could create a TExT “training website,” and then purchased a plug-in called LearnDash, which effectively turns WordPress into an online learning management system. The one-time cost for the LearnDash license was a mere $130.

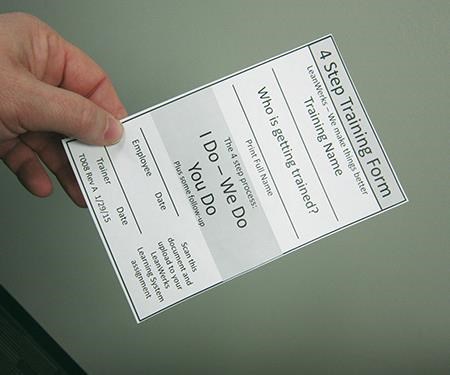

Using this as its platform meant documenting and presenting its curriculum was as simple as creating a website, although it more closely resembles a company Intranet. Employees can visit the password-protected TExT site at home or at work to access lessons that Mr. Harbath has made available to them. What’s key is that the program is set up that way so employees can’t proceed to the next lesson in a course until they demonstrate complete understanding of the current one. This is accomplished applying the simple “I do, we do, you do” learning model, followed by a clear demonstration of the new skill to a senior member of the staff who signs off on a training form such as the one shown on the previous page. Once this completed form is scanned and uploaded to the learning management system, Mr. Harbath is notified and can allow the employee to access the subsequent lesson. This continues until all lessons within a course are completed, at which time Mr. Harbath allows access to the next course. LeanWerks lets apprentices study lessons on company time, but Mr. Harbath says that more of their time at the shop is dedicated to demonstrating their understanding of concepts on the shop floor rather than reviewing lessons.

Many of the course lessons feature shop-produced instructional videos related to parts, practices and processes that are specific to LeanWerks. For example, one lesson demonstrates how to properly braze carbide tips onto machined shafts in the assembly of oilfield choke valves. The cost to produce the initial batch of approximately 130 training videos wasn’t high. The shop invested in a basic video camera and separate microphone, and hired an intern from nearby Weber State who was studying multimedia journalism to film and produce the videos over a span of six months. Videos are uploaded and accessed from Vimeo, a video sharing website. Mr. Harbath says the shop chose Vimeo for security purposes, because the training videos uploaded there can only be accessed through the TExT website. (See the top of this article for an example of one of the shop’s training videos.)

What’s nice is that the training videos provide value beyond “training.” They also serve to standardize a given process. Documenting all the steps necessary to complete a task in a video leads to consistent processes without variability. This might not be the case with less formal training initiatives in which an apprentice shadows various people on the shop floor, each of whom might carry out a task differently. Plus, if a production problem arises, shop personnel can always go back to the training video to verify that the proper procedures were followed.

It is also possible to provide LeanWerks’ suppliers or customers with access to certain TExT videos. For instance, vendors can view videos showing how part inspection should be performed following the subcontracted work they were hired to perform. Similarly, in cases in which a customer has asked the shop to perform corrective actions for a given job, LeanWerks can not only present documentation proving that the corrective actions have been taken, but it can also provide the customer access to a video showing precisely how the shop changed its process to remedy the issue. These examples demonstrate the flexibility inherent to this Web- and video-based training platform.

Next Steps: Achieving DOL Certification

In an attempt to further entice people to consider a career at LeanWerks, the shop is working with Weber State to combine TExT with a manufacturing engineering technology associate degree. This four-year program consists of 572 classroom hours at the university and 8,000 hours in TExT. In fact, LeanWerks will present this program to the DOL at the beginning of this year and expects its approval by mid-2016. This will mean employees embarking on this program will have the opportunity to earn DOL-recognizable and transferable certified journeyworker credentials, in addition to the associate degree.

LeanWerks is also a member of the National Tooling and Machining Association (NTMA), and Mr. Leland is trustee for its Northern Utah chapter. Last year, he approached the Governor’s office requesting a $150,000 grant to assist chapter members in developing machinist apprenticeship programs. The chapter won the grant, and Mr. Leland says it will also be used to launch what he foresees as being an ongoing marketing program among participating shops to generate public interest in manufacturing careers.

To date, 65 people have participated in the TExT program, although a few had to be let go during tough business conditions. However, Mr. Leland says LeanWerks is now looking to bring new candidates onboard, given that growth has returned as the shop continues to expand into new markets. He feels his shop’s individual efforts in developing the TExT program combined with his NTMA chapter’s marketing program will help his company attract and cultivate the type of quality shopfloor talent LeanWerks will need moving forward.

Related Content

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)