How To Machine Aircraft Titanium (Introduction To A Series)

Choose cutters, depths and tool paths with attention to particular steps in the process, and you can machine titanium more efficiently than you might suspect. Boeing offers practical tips.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreNew aircraft designs that make more extensive use of composite materials make more extensive use of titanium at the same time. Compared to aluminum, titanium is more compatible with composites in aircraft assemblies. As a result, the Boeing 787 Dreamliner, which is 50 percent composite materials by weight, is also 15 percent titanium by weight. That is significantly more titanium than the previous (heavier) Boeing 777.

Obtaining enough titanium to meet the needs of this latest generation of aircraft has been a challenge. Titanium prices have risen in response to the demand, and new capacity for producing titanium alloys is coming online. Still unaddressed, however, is the question of machining all that titanium. While no one can say for sure, it seems unlikely that there is currently enough titanium machining capacity to meet all the needs of the various high-titanium-content planes being introduced to the market. One way or another, the aircraft-industry supply chain will have to realize more of this capacity. Shops will be asked to machine more titanium than ever before, and also to machine it faster.

One of the leading organizations in the study of just how to do this is the Boeing Research and Technology group (BR&T) based in St. Louis. Boeing researchers here develop techniques for more effective titanium machining—techniques that they convey to Boeing’s suppliers.

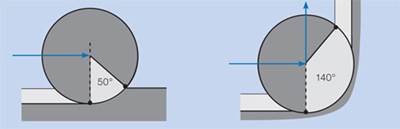

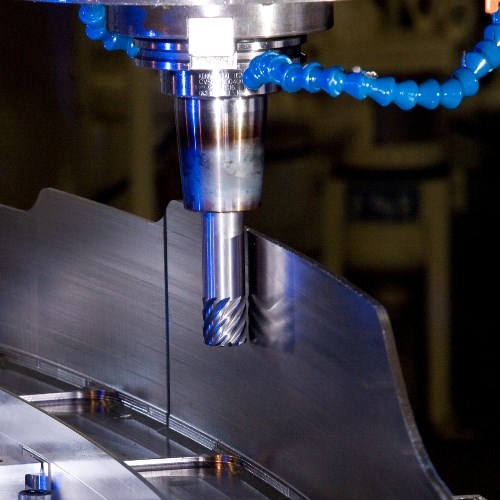

The archetypical titanium part is shown at right (the photo of the part held in a hand). The machining of aircraft structures made of titanium, like those made of aluminum, is fundamentally an exercise in machining pockets. Aircraft parts, with their webs and ribs, are made of many pockets. The pockets are particularly deep on the 787, because some deep-pocket aluminum parts have been replaced with titanium. Therefore, the pocket machining challenges are that much greater.

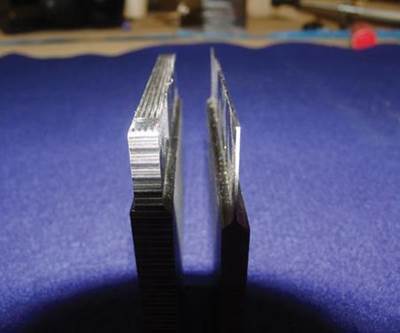

In aluminum, machining any particular pocket such as the one shown might not involve separate roughing and finishing operations. Titanium is different. Aircraft-industry manufacturers have learned to precisely cut aluminum at relatively consistent radial depths that allow even a heavy depth of cut to complete a wall or rib. But in titanium, the slow cutting speed means that roughing and finishing are still needed in order to remove the volume of material productively. As a result, machining a titanium part effectively involves a series of discrete operations, with different proven techniques at each step.

Those techniques are outlined in the collection of articles in the links under “Editor Picks” at right. The information comes from BR&T (or, in the case of one of the articles, from a major cutting tool supplier). As the articles describe, machining titanium aircraft parts productively does not necessarily demand a new machine tool or even any particular style of machine.

It also does not require great cost. The final article at right makes this clear. Any of the techniques in the articles below might be applied separately, but together, they produce a radically different titanium milling process that is likely to save not only time, but also considerable expense.

Editor’s note: You can read other parts in this series by clicking on Read Next (to the right).

Related Content

Schwanog Custom Form Tools Reduce Cycle Times

IMTS 2024: Schwanog’s insertable form tool system supports the manufacture of precision parts for industries such as medical, automotive, aerospace and others.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreSolar Atmosphere Receives Boeing Approval for Vacuum Oil Quenching

The approval was granted for oil quenching of alloy steels in the company’s new furnace, the Neo.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreRead Next

How To Machine Aircraft Titanium: Getting The Metal Out

Part of a series of articles on machining pockets in titanium parts, this article describes various options for roughing the hard metal efficiently.

Read MoreHow To Machine Aircraft Titanium: The 8-To-1 Rule For Finishing Walls And Ribs

Part of a series of articles on more efficient machining of pockets in titanium parts, this article makes the case for a tool with many cutting edges, and describes how best to apply it.

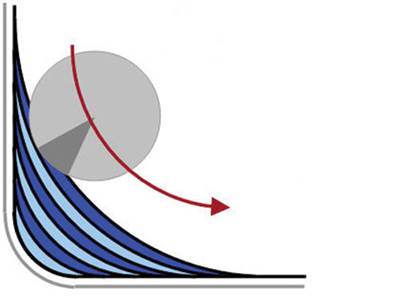

Read MoreHow To Machine Aircraft Titanium: Plunge And Sweep For Finishing Corners

Part of a series of articles on more efficient machining of pockets in titanium parts, this article describes an effective approach to finishing internal corners.

Read More

.jpg;maxWidth=300;quality=90)